Single Drive Axles Could Reduce Your Fuel Bill

[Stay on top of transportation news: Get TTNews in your inbox.]

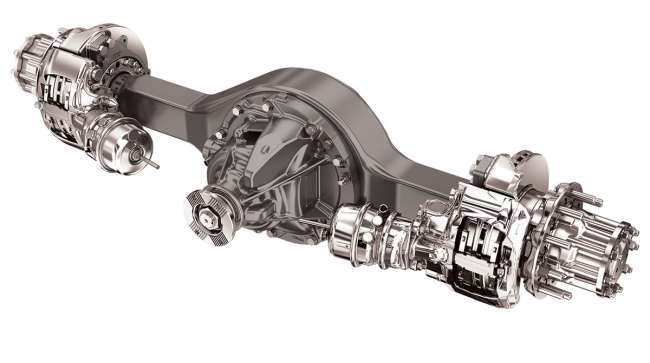

When it comes to spec’ing, getting the best fuel economy is about building a tractor with all the right pieces. Even with the best basic specs, additional fuel savings will come from substituting a single drive axle for the standard tandem axle drive system. Building a 6x2 drive axle will allow 80,000 GCW under the bridge law. The single driving axle has to handle the same amount of power, so why does it save fuel?

“While the frictional losses apply, the primary loss is attributed to churning — the ring gear and pinion rotating through the gear oil,” said Meritor’s Dale Kwasniewski, senior director of engineering. “The tandem axle has three gear sets in mesh generating churning losses, versus one. Plus, between the two axles of the tandem, there are 12 roller bearings while the single axle has only four.”

Steve Mastroianni, senior manager of product planning for commercial vehicle steer and drive axles for Dana, agreed, saying, “Any time there is an additional gear mesh, there are power losses. With a single axle configuration, two gear meshes are eliminated.”

Baxter

How much fuel will be saved?

“A 6x2, single drive axle setup can reduce driveline friction anywhere from 2.5% to 5% by only needing one drive axle while having the load capacity of a tandem axle,” said Mack Trucks’ Stu Russoli, highway product manager. “The liftable pusher adds to this by being able to lift the forward tandem axle tires off the ground to reduce drag. To calculate savings with the liftable pusher, it’s necessary to figure out how much of the time the pusher will be lifted.”

According to Chris Stadler, product marketing manager at Volvo Trucks North America, fuel savings is dependent on configuration and application. “We tell most of our customers that a 6 x 2 versus a 6 x 4 will save 1-3% fuel based on proper use of this technology,” he explained.

We tell most of our customers that a 6 x 2 versus a 6 x 4 will save 1-3% fuel based on proper use of this technology,

Chris Stadler, Volvo Trucks North America product marketing manager

Len Copeland, product marketing manager at Detroit Products, says to also factor in where fleets operate along with driving conditions. A 2-3% savings could be realized when the vehicle is used in the right conditions.

Dealing With the Elements

American tractors have historically been spec’d to drive both tractor tandems to give maximum traction, so how are snow, ice and mud handled?

More Q4 Calibrate Stories

►Proper Lighting Gives Fleets Brighter Maintenance Outlook

►Outsourcing Repair: Fleets Look to Third-Party Maintenance Services

►Scholarships Bring Opportunities to Students Looking for a Sustainable Career Path

►2022 Is the Year of Research and Discovery for TMC and Its Partners

►Freeze: Trucking Again Shows It Is a Resilient Industry

“The fleets who have adopted the 6 x 2 for weight reduction and efficiency gains have also addressed the reduced tractive effort associated with this configuration by specifying the optional driver controlled differential lock with the drive axle,” Meritor’s Kwasniewski said, adding that the vehicle will likely have automatic traction control as part of the ABS system.

“Some OEMs make use of weight shift during a low traction event to transfer more weight temporarily to the drive axle by reducing the air pressure in the air spring on the tag or pusher axle,” he explained.

Dana’s Mastroianni noted that the company offers its driver-controlled differential lock that’s used in most cases to improve traction. However, in the most successful 6x2 single axle arrangements, the drive axle is positioned at the rear-most end of the configuration to allow for load shifting between the pusher and drive axles.

“This prevents ‘dynamic whip’ that can create an unstable driving feel in the vehicle,” he said. “Additionally, in this arrangement, the adaptive loading biases weight during driving, creating an intuitive driving system that will help load the drive axle during slip events.”

In this [6x2] arrangement, the adaptive loading biases weight during driving, creating an intuitive driving system.

Steve Mastroianni, Dana senior manager of product planning for commercial vehicle steer and drive axles

Mack’s Russoli said the 6x2 tag axle setup is supplied by Meritor and is load biasing for traction in adverse weather conditions. Mack’s proprietary pusher axle setup was developed with Link Manufacturing and is automated to be self-lifting under lighter loads and allows for advanced load biasing for adverse weather.

“The liftable pusher is normally run at 50/50 and it can also be run at optimized bias for rain and bad weather at 53/47,” he noted. “There is also an enhanced traction mode, which biases even more than the optimized mode and is for extremely adverse conditions. It is also limited to slower road speeds.”

Volvo’s Stadler explained that in today’s 6x2 offerings, the system is designed to load the drive axle with more weight than the nondriven axle to provide the traction necessary while not exceeding the axle load limitations.

There is also an enhanced traction mode, which biases even more than the optimized mode and is for extremely adverse conditions.

Stu Russoli, Mack Trucks highway product manager

“Depending on the payload conditions, the load between the axles of the tandem could vary. In our proprietary 6x2 Adaptive Loading configuration, we are able to provide more traction support allowing the driver to be proactive when necessary and, again, not exceeding the axle weight limitations,” he explained. “Under light payload conditions, our system is designed to lift the nondriven axle of the rear tandem. By lifting the axle, the load will shift 10-15% to the steer axle, providing better steerability to the front axle, as well as more traction to the drive axle.”

Detroit’s Copeland stated that in a 6x2, it’s important to have the right conditions where routes are typically flat, geared for high top gear time, and GVWs of 80K or less.

“Tire slippage and wear can be accelerated in a 6x2 so it is important to work with your dealer to understand exactly how the truck will be used to ensure the right configuration is spec’d,” he said.

Single Drive vs. Tandem Drive

Alpha Drivers Testing and Consulting CEO Joel Morrow is an executive with Ploger Transportation involved with spec’ing. He says the Volvos Ploger runs have tractor tandems with a liftable forward axle and a rear tandem driving axle, and use adaptive loading to help ensure proper traction and minimal tire wear.

Stadler of Volvo said, “Our preferred 6x2 configuration is the pusher version with a liftable axle from Link Manufacturing and can be paired with either a Dana or Meritor single drive axle.”

For some, truck driving is a passion, and the best are America's Road Team Captains. ABF driver Nate McCarty, former America's Road Team Captain, and Elisabeth Barna, COO and executive vice president for American Trucking Associations, join us. Hear a snippet above, and get the full program by going to RoadSigns.TTNews.com.

Detroit’s Copeland says that Daimler Trucks North America offers a Hendrickson Optimaax system that also has the rear tandem axle powered and a forward tandem that is able to lift off the ground under the right driving conditions.

Morrow said the forward, nondriving axle is U-shaped so the driveshaft can extend rearward to the rear axle without interference. The goal is to maximize the weight on the driving axle.

“Adaptive loading loads the drive axle heavier than the forward axle until GVW is near 80,000 pounds,” he said, explaining that fleets experience trouble with tire wear in 6x2 configurations because a single drive axle will produce a significant amount of slippage unless adequately loaded. Morrow assures that adaptive loading solves the problem. He says that when the ABS system senses slippage, such as when on snow, the system will bias the weight on the driving axle and can max out at as much as 25% of GCW.

The percentage of Class 8 tandem tractors using single drive axles is still relatively small, by some estimates overall at 5% with some OEMs seeing 10-15%. Available ratios with single drive axles are nearly as wide-ranging as with tandems, though several manufacturers have their fastest ratios available only with tandem drive axles. Dana offers its fastest axles either way. 6x2 tractors are normally used only for linehaul operations. Logging or other off-road vocations still use only tandem drive axles. Thus, choosing a single drive axle over tandem drive in the right application should be seen as one more way to optimize fuel economy.

Want more news? Listen to today's daily briefing below or go here for more info: