2022 Is the Year of Research and Discovery for TMC and Its Partners

[Stay on top of transportation news: Get TTNews in your inbox.]

At American Trucking Associations’ 2021 Technology & Maintenance Council Fall Meeting & Transportation Technology Exhibition in Cleveland last month, energy was abounding during the council’s first face-to-face convocation in 18 months. To keep the momentum going, TMC is anticipating the ability to pursue several research projects under its agreement with FPInnovations/The PIT Group that had been deferred because of COVID impacts and restrictions. This partnership enables TMC to bring its own research projects directly to The PIT Group, including accessing on-track testing capabilities.

TMC had targeted two projects to be pursued during 2022, and will be using next year’s fall meeting to garner the industry support needed to undertake this research, through contributions of personnel and equipment as well as the essential financial support. By the end of this year, TMC aims to gather the essential contributions to enable the projects to proceed as planned.

The first project, developed by TMC’s S.2 Tire & Wheel Study Group, will re-create an on-track evaluation of the effects of total vehicle alignment on fuel consumption in tractor-trailer combinations, first studied by the Goodyear Tire & Rubber Co. in 2008 and documented in the report, “Factors Affecting Truck Fuel Economy.” For TMC’s updated evaluation, the same protocols will be utilized to look at combination vehicles that are equipped with currently available aerodynamic devices to determine the impact of misalignments. Since energy consumption is the most critical on-road operating expense, even small increments will add up over the many miles traveled.

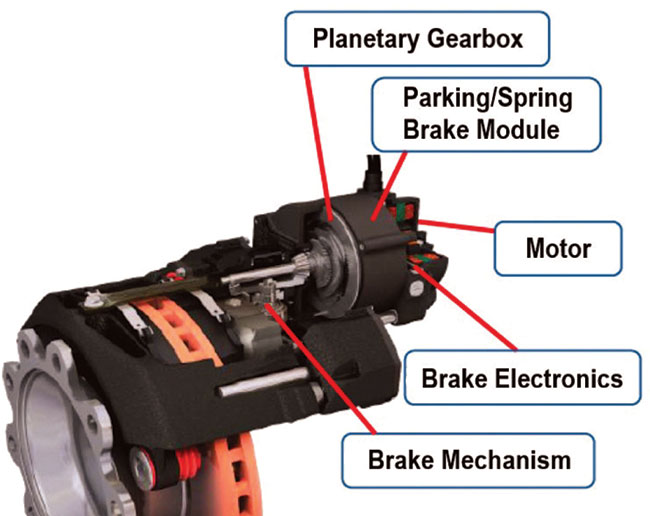

TMC will conduct on-track testing of Class 8 trucks equipped with prototype EMBs in order to demonstrate their performance in compliance with Federal Motor Vehicle Safety Standards. (TMC)

The methodology for these tests will utilize several of TMC’s Recommended Practices: TMC RP 1102A, TMC Fuel Consumption Test Procedure — TYPE II and TMC RP 642B, Total Vehicle Alignment: Recommendations for Maximizing Tire and Alignment-Related Component Life.

The PIT Group personnel will conduct the evaluation at the Transport Canada Motor Vehicle Test Centre in Blainville, Quebec. Initially, a baseline will be laid down, comparing fuel consumption via the RP 1102A procedure in the test combination vehicle and an identically spec’d control vehicle, both of which have carefully undergone total vehicle alignments per RP 642B. Then, deliberate misalignments will be introduced into the test vehicle for successive test runs, so as to allow for a structured comparison to Goodyear’s 2008 test results.

More Q4 Calibrate Stories

►Proper Lighting Gives Fleets Brighter Maintenance Outlook

►Outsourcing Repair: Fleets Look to Third-Party Maintenance Services

►Scholarships Bring Opportunities to Students Looking for a Sustainable Career Path

►Single Drive Axles Could Reduce Your Fuel Bill

►Freeze: Trucking Again Shows It Is a Resilient Industry

TMC will coordinate its project with The PIT Group’s annual Energotest in June 2022. This will be done in order to attain the most cost-effective use of resources by employing the same equipment and facilities for both evaluations. TMC is seeking financial support from the industry to defray these costs and has prepared a project prospectus for potential contributors.

The second project endeavors to conduct on-track testing of Class 8 trucks equipped with prototype electromechanical braking systems (EMBs) in order to demonstrate their performance in compliance with Federal Motor Vehicle Safety Standards for air-brake systems. This project would accomplish the second phase of TMC’s research into the potential for EMB systems for use in the trucking industry. TMC’s Future Truck Committee first proposed that the industry look at the potential benefits of various types of electronically controlled braking systems (ECBS), which employ control modules at the wheel ends in either air disc brake (ADB) applications or in EMBs, which substitute motor actuation of the brake calipers for pneumatics.

TMC’s Chassis & Brake Systems Study Group (S.6) will present a technical session at the fall meeting regarding the potential for employing new technologies in commercial vehicle braking systems, including discussion of both ECBS and EMBs.

The first phase of the EMB project, which evaluated the state of development of EMBs by original equipment manufacturers and brake system suppliers, was reported at TMC’s last face-to-face event before the pandemic, its 2020 annual meeting in Atlanta.

TMC

The PIT Group researched and evaluated 43 original equipment manufacturers for EMB technology and 16 OEMs will support TMC’s work in the Future Truck program. The focus is specifically around the future of commercial braking and the OEMs’ involvement in electromechanical brake development for Class 8 trucks. With the information provided, The PIT Group assessed the “state of design” of the respective technologies based on current data of available technologies, including how far they have gone toward building any prototypes, as well as technical challenges, limitations and obstacles anticipated or encountered.

The PIT Group found that various manufacturers were involved in research and development of EMBs, ranging from pre-prototype design all the way to prototype testing and on-road evaluation. Generally, EMBs under development are likely to be exclusively disc brakes. They could be employed without significantly altering existing axles, but in heavy-duty vehicles would require 24- or 48-volt power systems. Despite the differences inherent in each OEM’s electromechanical braking system, they claim to possess advantages over current pneumatic brakes such as increased wheel-end diagnostics and reduced stopping distance.

The study identified the potential for a Phase 2 of the project in order to justify the need to modify the regulatory framework to permit operational use of EMBs, especially if required to work in a mixed pneumatic/EMB architecture. TMC believes that there are now several OEMs that have developed prototype systems to the point to enable on-track evaluations of their performance, which has led the council to work with The PIT Group on a preliminary set of testing procedures.

TMC seeks contributions of these EMB prototypes to be installed initially in Class 8 straight trucks for testing for compliance with federal standards for braking system performance. The goal would be to determine if they perform at least as well as, if not better than, the pneumatic systems currently in performance. Presuming these commitments are forthcoming, TMC is looking to schedule track testing in the second half of 2022.

For more information on these projects, and on how your company or organization can support these TMC research objectives, email Jack Legler, TMC technical director, at jlegler@trucking.org.

Want more news? Listen to today's daily briefing below or go here for more info: