Achates’ Engine Brings Power, Lower Emissions

[Stay on top of transportation news: Get TTNews in your inbox.]

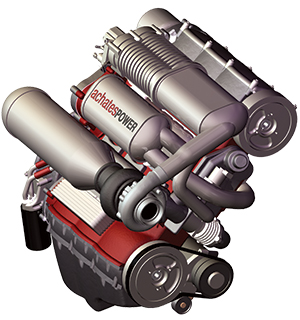

Achates Power of San Diego has developed a two-stroke truck diesel that has two crankshafts linked to two opposed pistons facing each other in a common cylinder.

The biggest advantage of this design is a tall, narrow cylinder, which reduces the area of metal surface for the volume of gases contained as compared with a four-stroke. This retains heat more effectively, which means a greater rise in pressure for the amount of fuel burned during the power stroke, and greater operating efficiency.

A 10.6-liter 3-cylinder opposed-piston engine can deliver 450 horsepower and 1,750 pound-feet of torque and replace a 13-liter four-stroke engine. Each cylinder replaces two normal cylinders, but total displacement is about 25% smaller, so the design has a slightly smaller bore and the stroke for each piston is just slightly shorter, with similar piston speeds. The engine can be smaller because a two-stroke fires every revolution.

Baxter

As Larry Fromm, the company’s executive vice president of business development, explained, one crankshaft sits at the top of the engine, and the other at the bottom. They are linked by a gear train to retain proper timing and transfer power. During compression, the two pistons approach one another, the upper one moving downward, and the lower one moving upward, until they nearly touch. Then, during the power stroke, the pistons move apart until each uncovers one set of ports in the cylinder walls.

The intake ports are located at the top of the cylinder and are uncovered by the upper piston as it reaches the top of its stroke, and the lower set — the exhaust ports — are uncovered by the lower piston as it reaches bottom center.

Air then flows down through the cylinder, forcing exhaust out in front of it, in a process called “scavenging.” Breathing is handled entirely by the two sets of ports. The engine employs two injectors, one on each side of each cylinder. The injected sprays both flow toward the center of the cylinder.

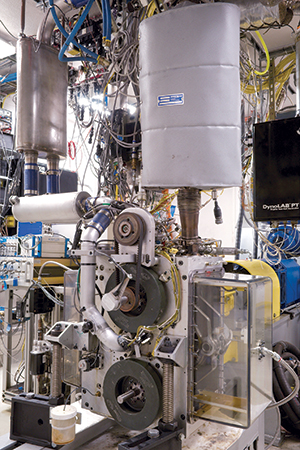

As one of Achates’ engines goes through a test cell, the two-stroke engine can run high EGR levels without soot because of its unique combustion system. (Achates Power)

The elimination of the cylinder head, which must be cooled by engine coolant, helps further with heat retention, as steel pistons run hotter than the lower surface of a head. The effective capacity of such cylinders is still larger than the four-stroke diesel it replaces because it fires twice as often. This means the amount of fuel injected during each power stroke is about half the normal amount, but the volume of the cylinder is much more than half what is provided in a four-stroke. The additional air and exhaust gas recirculation (EGR) per amount of fuel allows the fuel to be injected more quickly and to provide a faster burn while still avoiding a rapid rise in cylinder pressure and excessive noise. This further increases efficiency.

Also, less effort is needed to pump air in and exhaust out because the ports offer more area than valves. The engine has both a turbocharger and a blower, the latter either driven via a continuously variable transmission or equipped with a bypass valve. Under moderate loads, it is not “fully scavenged,” which means that less than a full new charge of air is forced through the cylinder, further reducing pumping requirements.

More Q2 EMU stories

This also retains some exhaust without the extra pumping needed to operate typical EGR systems. The engine also has a typical, water-cooled EGR system, but it is smaller and uses an EGR pump, which takes less power to run than standard systems.

General Motors studied opposed-piston engines and concluded that they produce about 13-15% lower CO2 emissions than state-of-the-art four-strokes.

The engine’s biggest advantage is its ability to retain high efficiency and still deliver much lower emissions. Cold starts typically produce high NOx because the SCR system does not work until it’s hot. With this engine, the flow of air is cut way down during warmup by slowing the blower. This accelerates the rise in exhaust temperature so the selective catalytic reduction (SCR) system lights off much more quickly. NOx is low prior to light-off because of the high levels of internal EGR that occur under such conditions. The net effect is 90% less NOx.

The Achates can run those high EGR levels without soot because of its unique combustion system. The two fuel sprays head toward the center of the combustion chamber and not toward the cool metal walls, remaining surrounded by air, rather than puddling on cool metal surfaces, which generates soot. They are subjected to what Fromm describes as “high tumble combustion.” Generating air turbulence with two pistons rather than one drives more air through the sprays, which also kills particulate.

The A48 Engine has the ability to retain high efficiency and still deliver much lower emissions. (Achates Power)

Significant improvements in various aspects of the design of the pistons and cylinder liners ensure oil consumption compatible with a four-stroke.

A 10.6-liter 3-cylinder design funded by the California Air Resources Board is currently being tested in a Peterbilt near the company’s plant in Denton, Texas.

Stationary tests conducted by Achates Power and Aramco showed the engine can operate at 0.02 grams NOx per brake horsepower-hour over the Supplemental Emissions Test cycle, meeting the 2027 California ultra-low NOx regulation, a 90% reduction from present standards.

The testing also showed the engine can operate more than 8% below the current standard of 460 grams of CO2, more than meeting the 2027 432 gram CO2 requirement over the same test cycle.

Want more news? Listen to today's daily briefing below or go here for more info: