Senior Reporter

Diesel Exhaust Fluid Sensor Failures Sideline Thousands of Trucks

[Stay on top of transportation news: Get TTNews in your inbox.]

Ongoing shortages of replacement parts for failed diesel exhaust fluid quality sensors are believed to be causing thousands of trucks nationwide to be disabled and parked.

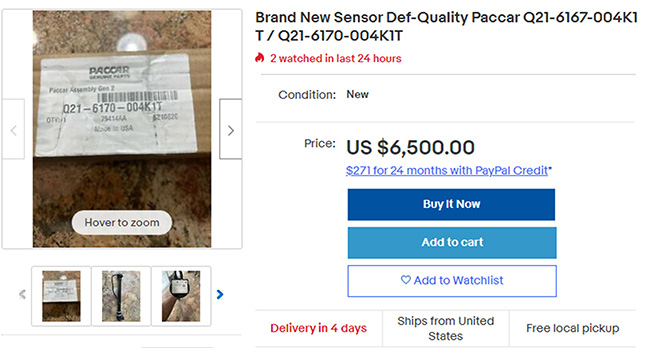

The sensors, which measure the quality and level of diesel exhaust fluid (DEF) in the tank, normally retail for roughly $300. But due to global computer chip shortages causing a backlog the part is being offered for sale — in some cases on digital retail sites such as eBay — for as much as $7,000, according to some industry technicians.

UPDATE, Oct. 7: Fixes are on the way

“It’s part of the global chip shortage,” Paul Enos, CEO of the Nevada Trucking Association, told Transport Topics. “We’re seeing trucks parked throughout the country. Just here in Nevada, 300 trucks are parked waiting for quality level sensors.”

Enos

Enos said there is a fail-safe that’s built into the selective catalytic reduction system of 2010 and newer trucks. “If it senses too much [nitrogen oxide] it will derate the engine,” he said.

Enos, chairman-elect of American Trucking Associations' Trucking Association Executives Council, and others say a software fix could at least temporarily get the sidelined trucks moving. However, that will require approval of a new software code by the U.S. Environmental Protection Agency. Absent that, running a truck with a defective sensor would not only cause its speed to drastically decline, but would violate current federal emissions regulations, he said.

“The interruption in the DEF quality sensor supply came about suddenly, but heavy-duty engine manufacturers have reacted with urgency to propose a software calibration to EPA and the California Air Resources Board to address customers who have experienced a sensor failure,” said Steve Berry, technical staff adviser with the Truck and Engine Manufacturers Association. “Getting commercial trucks back on the road to support the movement of goods and ensuring new truck orders can be delivered without delay is critically important. EMA and the OEMs are continuing to work with the regulatory agencies to finalize the technical solution and get it out to the field.”

Sensors that retail for $300 are being offered for far more on digital retail sites. (eBay)

Berry said the software solution could be available in some cases in as little as one or two weeks, but “will likely vary from manufacturer to manufacturer.”

Berry agreed the problem was created by computer chip shortages.

Marty Makrdichian, a service manager at Peterbilt Truck Parts and Equipment in Sparks, Nev., said a software fix would act as a sensor to monitor the quality and level of DEF in a truck’s tank, as well as permit a truck to move again.

“I don’t necessarily think this is a maintenance problem,” Makrdichian told TT. “I think the OEMs are trying to figure out exactly what is causing these things to fail. One of the theories that Peterbilt believes is causing the problem is excessive heat.”

Makrdichian said his dealership has “very, very few” of the replacement sensors available.

“There are so many trucks that have the sensor failures that dealers are unable to meet the demand,” he said. “I can place an order for every sensor that’s available every single day, and we have no idea when that sensor will show up. Usually we get them one at a time.”

“I’m hearing it’s a problem in multiple states,” said Mike Tunnell, ATA’s California-based environmental researcher. “Every state association I’ve talked to in the last few weeks has mentioned this issue. When the sensor goes out they need to get a replacement part that’s not available.”

Tunnell added, “The longer this goes on, the more trucks will likely have this issue. There’s definitely an urgency to this issue. We’re wanting a solution to be implemented as soon as possible. It sounds like the agencies and manufacturers have come up with a solution plan. But the solution needs to be developed and finalized.”

In a statement obtained by TT, EPA said it is working with the California Air Resources Board and the Truck and Engine Manufacturers Association to address the issue related to the ongoing shortage of computer chips and the impact it is having on replacement sensors.

“EPA and the California Air Resources Board have reviewed the proposed approach and believe it is appropriate for the companies to implement the proposed [interim software] solution going forward as quickly as possible,” the statement said. “The manufacturers must still develop new software code and test it to ensure the software can be installed on vehicles in the field.”

Sculley

The companies also will make available a similar software update for vehicles whose sensors have not failed, but are among a group of vehicles where such a failure could be expected to occur, EPA said. “This updated software is likewise expected to be available to service centers in the coming weeks,” the statement said.

Joe Sculley, president of the Motor Transport Association of Connecticut, has requested a meeting with an EPA official.

“This is a situation which has developed into a nationwide problem, and the industry is seeking immediate action by EPA as a means to help address it,” Sculley said in an email to EPA obtained by TT. “Right now trucks are disabled and parked as a result of the situation.”

Want more news? Listen to today's daily briefing below or go here for more info: