The Detroit News

Bollinger Motors to Build Battery Packs for Its Electric Trucks

[Stay on top of transportation news: Get TTNews in your inbox.]

Oak Park, Mich.-based electric-vehicle startup Bollinger Motors on Oct. 15 said it will produce its own battery packs for its vehicles according to a new design it developed and for which it has submitted a patent.

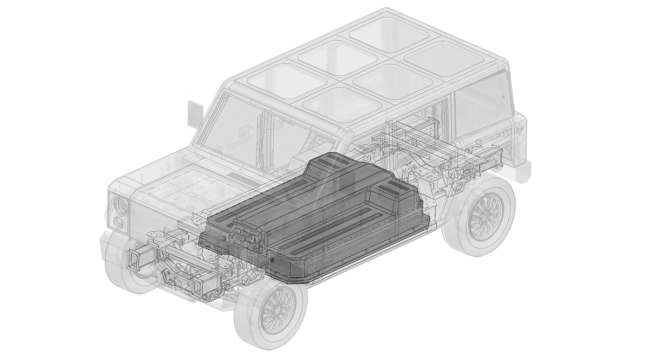

The design allows for larger battery-pack sizes that can store more energy and stay cooler but also requires fewer parts, making it lighter and needing less space than other configurations, the company says. The battery packs will be used in Bollinger’s SUVs, trucks and vans, and will be available for stand-alone applications.

“We really wanted to have the knowledge that goes into battery packs in-house,” Bollinger CEO Robert Bollinger said. “We could pay a lot of money to buy them from someone else, but this is a journey we wanted to have of growing and learning with the battery world. We think that is valuable for an EV company.”

Bollinger

Bollinger expects to announce a manufacturing partner for the company’s vehicles later this month or in November to go into production in 2021. Battery-pack production also is expected to begin next year, though Bollinger is examining whether to produce them in-house or with another partner. It has spoken with other battery-pack producers, including some in Michigan, Bollinger said.

The latest battery pack is the third designed by Bollinger engineers since its inception five years ago. It uses battery modules provided by Tier 1 suppliers. The pack goes underneath the vehicle and uses an I-beam that offers structural support and contains channels through which cooling fluid flows to cool the modules on either side of the beam. The company also developed the battery-management system that monitors the operation of the packs.

Because of the pack’s ability to keep cooler, Bollinger said the company is able to remove one of the two radiators that had been placed behind its vehicles’ headlights. The single radiator now goes behind the bumper.

“It frees up a lot of space in those two fender areas to hold more of the other components we needed,” Bollinger said. “It also allows for a big ‘frunk’ space so that storage is at maximum size for a passenger to use.”

The battery packs used in the vehicles will include strings of 35-kilowatt-hour modules totaling 140 kilowatt-hours. Pack sizes available will range from 35 kWh to 175 kWh or more that will be available to “make the right final solution” for individual commercial fleets, especially with respect to its new DELIVER-E van, Bollinger said.

Over the past few episodes, we've had the chance to listen to the experiences of industry leaders and the strategies and planning that go into finding the right people for your workforce. Host Michael Freeze reviews the most important bullet points, from technician and driver training to incorporating diversity in recruitment and retention. Hear a snippet, above, and get the full program by going to RoadSigns.TTNews.com.

The various sizes also could be sold to other companies for use. Generally, automakers have not sold battery pack formats themselves without a vehicle architecture with it, because there is not that level of standardization for them in the industry, notes Sam Abuelsamid, e-mobility analyst with Guidehouse Insight.

“Companies design products around those standard cell formats,” he said. “There’s not a buy-off-the-shelf battery pack right now.”

The company says its pack is suitable for heavier applications such as medium-duty trucks, agricultural and construction equipment. Bollinger has nine other patents and several others in review. It expects to hear a decision on its battery pack in the next year.

Bollinger’s focus is on low-volume sales of its $125,000 SUVs and trucks. It plans to partner with an automaker to produce the vehicles similar to how Nikola Corp. is looking to produce its Badger pickup with General Motors Co. Closure of that deal has been delayed following a scathing report by a sell-side investor to which Nikola objects.

That controversy has not affected talks and funding as Bollinger seeks out its own partner, Bollinger said. He added that partnerships like the GM-Nikola alliance are good for the industry.

“More and more suppliers will switch to electric,” he said. “Regulations in California to curb fossil fuels by a certain date and in other states make it better for everyone. In terms of the components we buy, there will be more volume out there and better pricing, making it more affordable.”

Want more news? Listen to today's daily briefing:

Subscribe: Apple Podcasts | Spotify | Amazon Alexa | Google Assistant | More

Distributed by Tribune Content Agency, LLC