Senior Reporter

Volvo Details Engine, Transmission Updates for Redesigned VNL

[Stay on top of transportation news: Get TTNews in your inbox.]

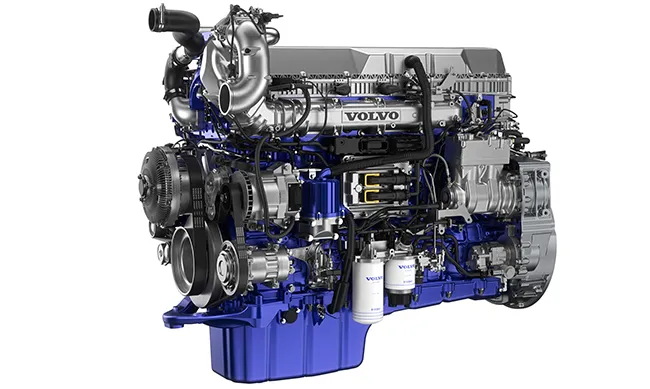

Volvo Trucks North America on Feb. 6 outlined a range of mechanical and technological enhancements to both its proprietary D13 engine and I-Shift automated transmission that helped the OEM achieve efficiency gains with its redesigned VNL Class 8 tractor, including a raft of changes to the engine’s architecture and programming, and mechanical adjustments to the transmission.

“As we’ve said, this is not just a face lift — it’s a 90% redesign of the product and the platform for all future powertrain solutions,” VTNA President Peter Voorhoeve said in a news release outlining the changes. He noted that the truck’s 10% fuel efficiency increase over its predecessor is the result of “radically improved aerodynamics and a dedication to improving upon our already class-leading powertrain offering.”

Voorhoeve added that the changes represent the company’s “collective efforts to reduce carbon emissions. A 10% savings in a nearly 300,000 Class 8 truck market would equate to the same carbon reductions delivered by 30,000 battery-electric Class 8 trucks.”

Changes under the hood include improving the efficiency of the turbo by minimizing heat loss through addition of insulation to both the unit itself and the compounding unit, while also installing a smaller compressor and turbine wheel. The company said the changes will enable the turbo to “recover surplus energy more effectively, converting it into usable power.”

The D13 engine now features a variable displacement oil pump, which employs adjustable vanes that adapt to the engine’s oil pressure demands to deliver more consistent oil delivery across operating conditions. (Volvo Trucks North America)

Inside the engine, Volvo engineers installed smaller needle control valves in the fuel injectors to provide improved fuel flow into the engine’s combustion chamber. The size reduction also provides for more precise and rapid control over the fuel flow rate out of the injector tip, VTNA said, leading to improved fuel atomization, better combustion efficiency and enhanced engine performance.

Residing inside the combustion chamber is Volvo’s new seven-wave piston. A follow-up to the patented six-wave piston the manufacturer introduced in 2017, the new design allows for additional directional control of the diesel engine’s fuel and air mixture to enable a more efficient combustion process, VTNA said.

Additionally, engineers decreased the size of the piston height and paired it with a longer connecting rod to minimize cylinder sidewall pressure. The manufacturer said these changes will decrease friction and improve overall performance by producing a smoother internal movement while reducing parasitic loss and increasing overall efficiency and engine longevity.

The D13 engine also now features a variable displacement oil pump, which employs adjustable vanes that adapt to the engine’s oil pressure demands to deliver more consistent oil delivery across operating conditions. By altering the vane angles, the pump can tailor its output to match the engine’s requirements, which can help prevent excess oil flow when not needed and maintain optimal pressure when conditions require it, VTNA said.

“This adaptability not only enhances engine efficiency by reducing the energy required to drive the pump but also minimizes unnecessary strain on the engine components, resulting in improved fuel economy and reduced wear and tear over time,” VTNA said.

Tegels

Changes to the truck’s I-Shift transmission, meanwhile, focused on both electronic and mechanical components. The changes, which VTNA said netted a 30% improvement in shifting speeds compared to earlier versions of the transmission, included overhauling its software and electronics system, including redefining computer algorithms. Engineers also reduced the unit’s clutch throw and introduced an enhanced clutch brake system.

“Vehicle efficiency transcends mere engine performance; it encompasses the synergy between various components, where the transmission plays a pivotal role,” VTNA Product Manager for Powertrain Duane Tegels said. “The transmission’s ability to optimize gear shifts, reduce energy loss and harmonize power delivery significantly influences overall vehicle efficiency, showcasing that a holistic approach beyond the engine is vital in achieving optimal performance and fuel economy.”

Tegels said the changes will result in more efficient gear shifts, which will result in shorter transition times and improved power delivery and acceleration.

The manufacturer on Jan. 23 introduced a complete redesign of its Class 8 VNL tractor, the truck’s first update since 2017 and the most significant since its 1996 launch, VTNA said. Order books are set to open in April for the new truck, with production set to begin in the third quarter of 2024.

The D13 engine offered in the new VNL has horsepower ratings ranging from 405 hp to 500 hp and torque ratings between 1,750 pound-feet and 1,950 pound-feet, VTNA said.

Want more news? Listen to today's daily briefing below or go here for more info: