Senior Reporter

Tractor-Trailer Interfaces Take Shape in Many Ways

[Stay on top of transportation news: Get TTNews in your inbox.]

Efforts to ensure the needed connections for exchanging more data between a tractor and trailer continue from many directions as electronics and sensors are increasingly coming to trailers, experts said.

Connector options were discussed during the virtual Spring meeting of the Technology & Maintenance Council of American Trucking Associations.

“Fleets, truck OEMs and trailer OEMs should get actively involved at a higher level to drive a consensus agreement on the path forward,” Paul Menig, chairman of the S.1 Next Generation Tractor-Trailer Electrical Interface Task Force, told Transport Topics.

TMC is underwriting new research aimed at evaluating trailer owners’ adoption of intelligence products and services that are becoming increasingly available throughout the industry.

The eSMARTT Trailer Survey [enhanced Safety, Maintainability And Readiness Through Technology] of rental/lease companies is scheduled to be presented during TMC’s in-person annual meeting Sept. 12-16 in Cleveland.

The TMC meeting last week was virtual.

“When you consider that GPS trailer tracking has been around for over 20 years and is still not universally accepted and implemented, it is easy to understand that getting to a fully eSMARTT trailer is going to take time even after the best pathways are defined,” said Charles Willmott, CEO at WillGo Transportation Consulting.

Willmott and Menig, who is also the CEO of Business Accelerants, conducted the survey and are analyzing the results for TMC.

Meanwhile, key issues included in the scope of S.1 include:

- The current tractor-trailer interface does not easily provide connections for high-speed communications such as needed for cameras, future safety systems and autonomous operation.

- The main 7-pin connector and two air lines provide basic on/off power. SAE J2497 [the standard for power line carrier communications for commercial vehicles] provides only a single data signal from the trailer to the tractor.

- Many optional connections exist for higher power, high-speed signaling and wireless communications to mobile devices used by the driver or service personnel.

- A forward-looking set of connections between tractor and trailer with backward compatibility for existing trailers is needed.

- Wired and wireless connections will be considered. Connections for air, power, low-speed signals and high-speed signals will be incorporated.

- Collaboration between organizations is needed, including TMC, SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization).

“Lots of new ideas and so-called ‘smart trailer’ products have been introduced in just the last few years by component suppliers,” Willmott said. “Individually, many of these products have outstanding benefits to carriers and other trailer owners, but collectively they produce a cacophony of noise I refer to as ‘innovative dysfunction’ that makes it incredibly difficult, expensive and risky for trailer owners to navigate and commit to future strategies.”

During the TMC presentation, John Cathey, field sales support manager for original equipment at East Penn Manufacturing Co., said absorbed glass-mat (AGM) batteries will give the “cycle counts you are looking for in trailer applications for lift gates and all the other power demands that you might have. AGM seems to be the preferred choice in the market today.”

Cathey added if liftgates or any other load is being spec’d, then a larger alternator and solar power “will most likely be required. This will improve the recharge ability of both flooded lead and AGM batteries.”

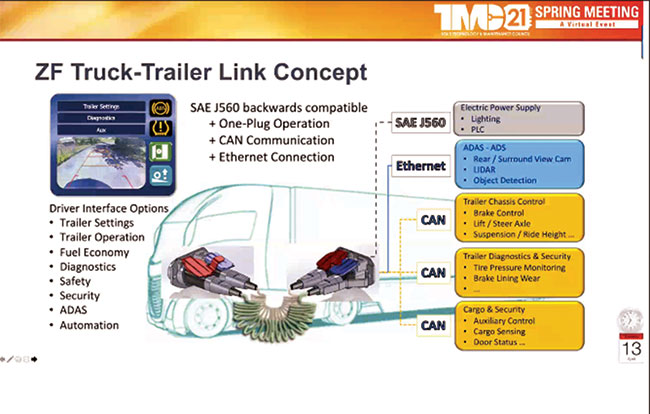

Wolfgang Hahn, system innovation leader for Wabco North America, a unit of ZF, said brake by wire, or electronic braking, is needed for advanced safety systems and autonomous operations. Sophisticated camera systems will have to use gigabit ethernet transmission technology.

That’s happening in Europe and Australia, Hahn said, and “the brake control system basically becomes kind of a spinal cord for this overall vehicle combination.”

Meanwhile, Dave Engelbert, chief engineer at Haldex, noted Europe is further ahead in terms of implementation of a communication bus between tractor and trailer and has been for several years compared with the United States.

He said European regulators are looking at having an additional requirement for object detection, versus ultrasonic, implemented in July 2022.

Very important Task Force work happening this week! #TMC21Spring offers a full slate of educational content along with 15 study groups and more than 100 task forces, which will shape the RPs for today’s and tomorrow’s fleet operations. Details https://t.co/Uo2IwU0rBn — Technology & Maintenance Council (TMC) of ATA (@TMC4Trucks) April 13, 2021

“They are seeing a demand for higher speeds of communication between the tractor and the trailer,” Engelbert said.

He added that the agricultural sector is further ahead than the trucking industry in deploying high-speed communications between the tractor and the farm implement. The Agricultural Industry Electronics Foundation (AEF) is leading that effort.

“They are currently talking to chip manufacturers to find one that can produce the chips they need for this high-speed ethernet,” Engelbert said.

“They have approached us both in Europe and North America about combining forces and joining them,” he added, for more purchasing power.

“We could learn something from them,” Menig said “and, potentially scale better, by collaborating with them.”

Menig said chips are used in trailers’ anti-lock brake systems, trailer tracking, tire pressure monitoring for sensing pressure and monitoring and in electronic controls for liftgates. “There will be many more in the future.”

Want more news? Listen to today's daily briefing below or go here for more info: