Staff Reporter

Technology Should Be Majority Player in Supply Chain, Coyote Says

[Stay on top of transportation news: Get TTNews in your inbox.]

Some people fear the rise of robots, artificial intelligence and machines, but supply chain managers should not.

Instead they should embrace the new technology of the 21st century, giving AI and other technologies 60% of tasks, according to a recent report by Coyote Logistics, a UPS Inc. subsidiary based in Chicago.

Have you downloaded Coyote's Technology + Humanity research report? Get access to our original research at no cost now: https://t.co/ab9WYEpt9U #CoyoteInsights pic.twitter.com/auXDGrIkfW

— Coyote Logistics (@CoyoteLogistics) October 2, 2019

The mix — 60% technology and 40% human expertise — was recommended in Coyote’s “Tech + Humanity” study, conducted in partnership with Martec, a third-party research firm.

The survey revealed that balance was needed to optimally manage supply chains, “reaffirming Coyote’s long-standing position that the two must go together to succeed in an evolving world,” according to the Sept. 26 report.

But humans always will have a role, Coyote found. Supply chains of the future require a blend of both technology and human support — not one or the other, Chief Marketing Officer Christina Bottis said in the survey.

The survey explored perceptions from shippers and carriers. Coyote also released an online Tech + Humanity assessment that enables shippers and carriers to find out which they favor more — technology or human expertise.

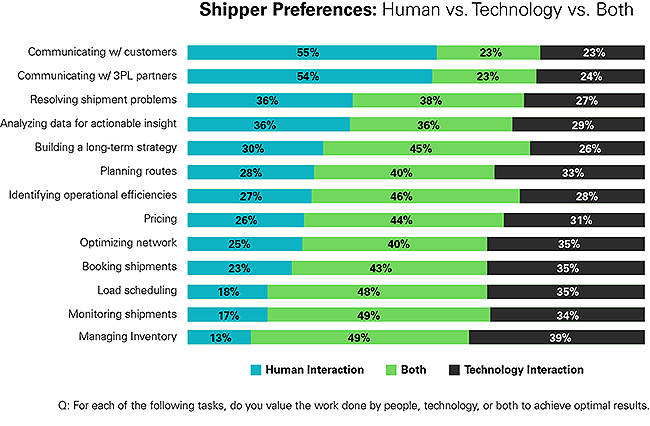

The Tech + Humanity survey analyzed which of the 13 tasks are best suited for human expertise, which functions can be optimized with technology and which require a combination of both.

Coyote officials said human expertise is irreplaceable in creative, decision-making and strategic-thinking tasks, such as communicating with customers and resolving shipment and delivery problems. Shippers and carriers reported that technology is best positioned to strengthen operational functions such as managing inventory and booking shipments.

One Coyote official told Transport Topics that humans don’t have to worry about being replaced.

“Our research does not point to replacing manpower with technology or AI,” Nick Verceles, senior vice president of North American sales, said in an email. “What the Tech + Humanity research shows is that even for tasks that skew more toward technology, there is still a necessary, irreplaceable human component. What shippers and carriers need to consider is not how to replace manpower in these functions, but how to strengthen them even further with technology.”

Verceles said one example is investing in a warehouse management system that can use technology to track and monitor inventory with more accuracy and speed than manual work. At the same time, warehouse employees can shift their focus to analyzing how much volume is moving in and out, or what times movements spike.

“By leveraging technology to better automate parts of those tasks, supply chain professionals can refocus their personnel on streamlining operations and better planning,” Verceles said.

Coyote offers an online assessment — a short quiz that supply chain professionals can take to find out directionally how they currently balance technology and human expertise, Verceles told TT.

Coyote is a third-party logistics provider that matches more than 10,000 shipments a day. The Martec Group is a research agency based in Royal Oak, Mich., and Chicago.

UPS, Coyote’s parent company, ranks No. 1 on the Transport Topics Top 100 list of the largest for-hire carriers in North America.

The use of data and technology — and even AI — is growing in the freight industry, largely because it returns results and cost savings, two trucking industry officials told TT. The “60-40” mix may sound large, but it is not, one official said.

Coyote Logistics

“It’s not something to fear,” said Steve Chaffee, senior director of transportation data analytics at Hitachi’s Center for Social Innovation. “Those numbers don’t surprise me at all.”

Chaffee said the experience of a mechanic doing work over 30 years is invaluable, but so are the records of maintenance.

Eventually, some supply chain and trucking industry tasks can and will be identified as being appropriate for robots, such as inspections, Chaffee said. But he expects some resistance at first.

“It’s very much a ‘show me’-type industry,” he said.

Yet, using technology and data is key to fleet success and can reduce truck breakdowns, said Jim Buell, executive vice president of sales for FleetNet America, a Cherryville, N.C.-based third-party maintenance provider.

Buell told TT that trucking firms often compare their unscheduled maintenance events with industry averages, instead of the best in the industry. Trucking fleets usually average 9,400 miles between breakdowns or technical issues, but the best fleet goes 43,000 miles, Buell said, using his research.

Using technology and data to understand and avoid trouble can save fleets time, the most valuable asset of all, he said. Not using data will lead to imbalanced results.

“Without data, you are just guessing,” Buell said.

Want more news? Listen to today's daily briefing: