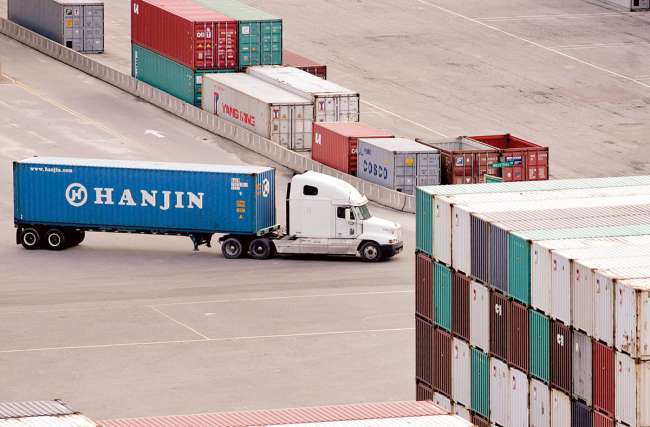

Supply Chain Execs Explain Lessons Learned a Year After Hanjin Disruption

On Aug. 31, 2016, the Hanjin Shipping Co. shut its doors, filing for bankruptcy protection and kickstarting a series of problems for port authorities, truckers, cargo owners, freight forwarders and equipment providers to solve on the fly.

A year later, industry executives said they’ve learned a lot about how to minimize the fallout of another insolvent ocean carrier.

Jon Slangerup, then executive director at the Port of Long Beach, Calif., flew to South Korea multiple times in the months prior to the bankruptcy, believing that the government would bail out Hanjin because the ocean carrier was too big to fail. He said that had the bankruptcy process not caught everyone off guard at the outset, things may not have been so chaotic.

LOSSES ADD UP: Carriers say Hanjin hit their balance sheets hard.

Today, Slangerup is chairman and CEO at American Global Logistics. He contends that cargo owners must consider the benefits that a freight forwarder can provide during the next disruption, whether a bankruptcy or a port strike.

“You need to develop agility in your plans to deal with changes that inevitably occur in this business,” Slangerup said in an interview with Transport Topics. “Our customers want to know what’s going on and see as much as they can. They want visibility so that they can do the best job in anticipating what might happen to have the flexibility to adjust.”

Tim Rue/Bloomberg News

For Sanne Manders, chief operating officer at tech-based logistics provider Flexport, one important lesson was that cargo owners should diversify their freight.

“First, you get what you pay for. A really low rate might not always be what it seems,” he said. “Second, maybe instead of one contract where I guarantee 1,000 TEUs [industry-standard 20-foot containers], I might sign four 250-TEU contracts. It makes your life more complex because it’s more to manage, but that’s something we do very well.”

Intermodal Cartage President Joel Henry said he closely monitors the Altman Z-scores, a formula used to predict the likelihood of a bankruptcy. The trucking company’s parent, IMC Cos., ranks No. 84 on the Transport Topics list of the top 100 for-hire carriers in North America.

“We’ve now told our clients that if they want to continue with a troubled line, then there’s a financial obligation for the dray in the event of a bankruptcy or they somehow pay us directly for our services,” he said.

You need to develop agility in your plans to deal with changes that inevitably occur in this business.

Jon Slangerup

Last September, trucking companies grappled with whether to pick up and deliver containers to their final destinations, unsure of who would pay them. Cargo owners often pay a steamship line to manage the entire end-to-end or door-to-door logistics, including the drayage. And, after the cargo was delivered, truckers struggled to find locations to return the empty containers and separate them from the chassis underneath. Equipment piled up and turnover ground to a halt.

“It simply took too long to be able to come up with a solution on the containers,” said Ron Joseph, chief operating officer at Direct ChassisLink Inc.

“The truckers are probably the hardest hit in the value chain when a crisis like that happens because they care about how many turns they can make in a day. When that’s interrupted, their livelihood is immediately and dramatically affected,” Slangerup added.

By the end of September 2016, more than 10,000 chassis were trapped under Hanjin boxes, nearly three times the typical average, according to Flexi-Van Leasing Inc. In Southern California, there is a “pool of pools” of about 72,400 chassis from Flexi-Van, Direct ChassisLink and Trac Intermodal.

“People were suggesting that we needed to add more chassis. We asked why terminals weren’t opening their yards to take the empty containers. There was just a lot of finger-pointing. Hopefully, one of the lessons learned is that finger-pointing didn’t help anyone. It was, quite frankly, an embarrassment to the industry,” added Phil Connors, Flexi-Van’s executive vice president at the time, who has since retired.

Going forward, Joseph and Connors urge port authorities to formulate a plan with terminal operators to identify a pre-determined location to return containers during an emergency and quickly communicate those procedures in the initial aftermath.

But Quik Pick Express CEO George Boyle believes the Hanjin incident revealed a flaw in the pool of pools and taught truckers that they should pursue private alternatives. “We’re different because we purchased chassis of our own years ago. Why did we do that? Because we wanted to eliminate that risk.”

He said that after Hanjin some trucking companies finally decided to invest in their own chassis or to lease more from the Harbor Trucking Association private pool.

Earlier this year, Yang Ming Marine Transport sparked new worries after recording a $500 million loss for 2016. The ocean carrier quelled some of those fears when Transport High-Efficiency Alliance announced the formation of a fund to assist in a financial emergency. The ocean freight group consists of Germany’s Hapag-Lloyd, Japan’s MOL, K Line and NYK Line, and Taiwan’s Yang Ming Line. No details on the size of the fund have been released.