Regular Realignment Is a Savings, Not a Cost

Tire wear often is blamed on a number of things, and many times, on the brand of the tire. But aggressive tire wear is a symptom that something else is wrong with a truck.

Peggy Fisher, president of TireStamp Inc., maintains that after proper inflation, total vehicle alignment (tractor and trailer) has the greatest impact on tire wear and fuel economy.

As many as 70% of heavy-duty trucks going down the highway exhibit irregular tire wear caused by axle misalignment, according to Mike Beckett, president of MD Alignment Service, an Iowa-based consulting firm. And these are not tired, worn trucks. Many are brand new from the manufacturer.

Sturgess

A half-inch misalignment will shorten tire life 18% on the drive axle and 31% on the steering axle, according to a laser alignment tool promotional video by Axle-Tru Alignment Systems. Dog-tracking, or the sideways offset of a trailer while running down the road caused by misaligned trailer axles, could account for a 2% fuel penalty alone, according to the video.

“In tests conducted over the last few years, it was found that properly aligned vehicles could significantly control irregular wear and increase tire mileage,” said Fisher, a former general chairman and treasurer at American Trucking Associations’ Technology & Maintenance Council. “Not only does vehicle alignment play a significant role in extending tire mileage and reducing tire costs, but proper alignment also makes vehicle handling predictable, driver control easier and improves fuel economy by as much as 2% since tires that roll straight and true have much less rolling resistance than tires that are dragged down the road at an angle.”

A recommended practice by TMC suggests that new trucks have an axle alignment no more than 90 days after being put into service.

Improper toe settings are the most common misalignment problem and have the greatest effect on truck tire wear, said Fisher, who currently chairs TMC’s S.2-Tire & Wheel RP Updates task force. Toe is the setting of the front axle alignment and is generally set to point the front wheels toward each other by 1/16th of an inch. This allows for deflection in the steering system so the wheels are truly parallel when running down the road. And of all alignment issues, it’s probably the easiest to correct, she said.

Tandem axles that are not parallel to each other and/or axles that are not perpendicular to the chassis centerline will affect the wear on steer tires, Fisher said. Drive axle misalignment is the second most common cause of alignment-related irregular tire wear.

According to TPA Solutions, alignment costs run about $250 at a shop. The company makes the Protrak QCT, a laser alignment system that’s ideal for small fleets and owner-operator cooperatives. This and similar systems that use lasers to accurately set alignment are available from several sources and fleets report significant improvements in tire life from using them regularly.

Steph Sabo, a former fleet manager who is now in the truck repair business as the owner of Illinois-based Fast Truck and Trailer, said that during his days as a maintenance manager, he would routinely align every new truck. He would do it again at annual intervals or when suspension work was done. Sabo used an alignment service.

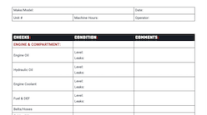

But for an inexpensive alignment, the ATTACC Plus procedure recommended by Michelin uses only tools found in most toolboxes. It is the least expensive procedure, but is moderately time consuming and at times requires two technicians to handle the measurements.

Michelin provides a worksheet on which to enter the results and calculate front axle toe, drive axle parallelism and any drive axle thrust. These are the main alignment issues on the tractor. Trailers are checked with the same tools to eliminate dog-tracking or out-of-parallel axles.

Regardless of the tire brand used, if it’s showing evidence of uneven wear, it is worth contacting the tire company for advice on procedures on setting alignment.

At the other end of the cost spectrum are the fully automated laser alignment systems, such as those from Hunter, Bee Line and Josam, to name a few. They usually require a dedicated bay. These alignment systems run tens of thousands of dollars but are efficient in terms of minimizing vehicle downtime and maximizing technician efficiency.

Fleet size will dictate where the dollar decision falls. But given that fuel and tires are top expenses for fleets, regular realignment is not a cost. It is a savings.