Bloomberg News

Manufacturing Growth in US Eases as Supply Chain Issues Linger

[Stay on top of transportation news: Get TTNews in your inbox.]

Persistent supply chain challenges continued to weigh on U.S. manufacturers in October, lengthening supplier delivery times and bloating a measure of inventories.

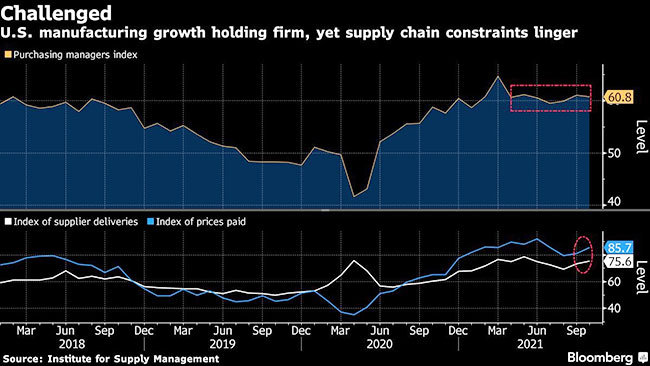

The Institute for Supply Management’s gauge of factory activity fell to 60.8 from 61.1 in September, according to data released Nov. 1. Readings above 50 indicate expansion. The median projection in a Bloomberg survey of economists had called for 60.5.

ISM’s gauge of supplier deliveries rose to a five-month high in October, indicating longer lead times faced by producers for raw materials. Labor shortages, intermittent shutdowns and record goods imports have overwhelmed the nation’s ports and delayed deliveries.

That’s also contributed to a sharp rise in the group’s inventory index, which swelled to its highest level since 1984. The gauge also captures growth in work-in-progress inventories and challenges distributing finished goods.

In this episode, host Michael Freeze asks, how are companies saving money by leasing trucks rather than owning? For answers, we speak with Jim Lager of Penske Truck Leasing and Al Barner of strategic fleet solutions at Fleet Advantage. Hear a snippet above, and get the full program by going to RoadSigns.TTNews.com.

“Companies and suppliers continue to deal with an unprecedented number of hurdles to meet increasing demand,” Timothy Fiore, chairman of the ISM manufacturing business survey committee, said in a statement.

“All segments of the manufacturing economy are impacted by record-long raw materials lead times, continued shortages of critical materials, rising commodities prices and difficulties in transporting products,” Fiore said.

The average lead time for materials used in the production process rose to 96 days in October, the highest in data back to 1987. Average lead time for supplies used for maintenance, repairs and operations climbed to 49 days, also a record.

Meantime, new orders eased, which helped to slow the pace of backlog growth. While ISM’s measure of production was little changed, the bookings gauge dropped to 59.8, its weakest level since June 2020.

Materials costs continue to climb. A gauge of prices paid rose to a three-month high of 85.7 in October.

Sixteen manufacturing industries, led by apparel, furniture and textiles, reported growth last month.

Manufacturers do appear to be having some success increasing factory headcounts, with ISM’s measure of employment rising to a three-month high of 52.

The figure precedes the government’s monthly jobs report at the end of this week. Nonfarm payrolls are expected to rise by 450,000 in October, while factories added almost 30,000 jobs.

Want more news? Listen to today's daily briefing below or go here for more info: