Technology Fuels a New Future for Internal Combustion Engine

[Stay on top of transportation news: Get TTNews in your inbox.]

According to fleet executives as well as fleet maintenance managers, the death of the internal combustion engine may prove to be greatly exaggerated in spite of the excitement about electric powertrains. Industry leaders have been working to give the basic piston engine an extended life.

SPARK: Go in-depth on the future of ICEs in our half-day virtual event

The secret to this life extension for ICEs lies in the use of greener fuels as they allow reduced cost of fuel and maintenance for fleets while at the same time reducing greenhouse gases. These newer engines will also have a much easier time keeping up with stringent upcoming emission standards for primary pollutants like NOx, particulates and unburned hydrocarbons. Experts believe the likely final result of new fuel technology will be a far greener future that, at the same time, will often resemble the familiar present.

“The problems of the diesel engine are more related to the fuel than to the engine itself,” said BJ Johnson, co-founder and CEO of ClearFlame Engine Technologies.

The new engines will all use lower-carbon fuels, many of them derived from nonmineral sources that derive their energy directly from the sun, thus reducing CO2 in the atmosphere. Renewable natural gas will capture low-carbon methane from present sources like farming and landfills, and burn the fuel in engines. Although these engines release CO2, (CO2 is only 1/30th as potent a greenhouse gas as methane), the amount is less than when running on diesel fuel, resulting in a “carbon-negative” environment.

An engine is retrofitted with the ClearFlame combustion system, including a ClearFlame Engine Control Module. (ClearFlame)

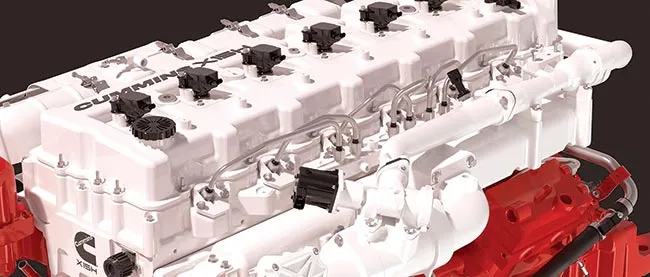

Cummins will introduce the X15N in 2024, a spark-ignited natural gas engine that will be the first of the company’s engines based on their new fuel-agnostic platform that uses common parts below the cylinder head. “The natural gas engine will have a unique cylinder head for the necessary cooling, and its spark ignition system,” said David King, Cummins’ North American on-highway product manager, natural and renewable gas engines, adding that the 15-liter engine will be a game changer because of its “get up and go.”

The natural gas engine will have 1,850 pound-feet of torque available by 1,100 rpms and 1,800 pound-feet at the X15 diesel’s torque peak of 1,000 rpms. King also noted that it’s quieter than a diesel whether idling or generating grunt.

Johnson

Westport Fuel Systems CEO David Johnson describes a different type of natural gas engine based on Rudolf Diesel’s original theory. Powered via its high pressure direct injection system developed by Westport, the engine burns natural gas as its primary fuel with a tiny shot of diesel for ignition. The patented HPDI injector provides both fuels under extreme pressure via a dual concentric needle design. It retains diesel-like efficiency, power and torque, but needs to use liquefied natural gas so its onboard fuel pump can produce the high-injection pressure needed. It will also need a selective catalytic reduction system for NOx and a simple diesel particulate filter. Westport and Volvo Group recently signed a letter of intent to use the system to reduce CO2 emissions, especially when renewable natural gas is the fuel.

Hyliion created a hybrid model, ERX Powertrain, which runs on renewable natural gas. It combines a large battery pack at the rear of the cab with a 12-liter engine that runs on RNG. But in November of 2023 it announced it plans to exit the Class 8 electric powertrain business, after completing a strategic review of its options for the unit. Instead, the Austin, Texas-based original equipment manufacturer will focus its attention on the less costly commercialization of its fuel-agnostic Karno stationary generator.

How effective have third-party services proved to be for fleets? Let's find out with Michael Precia of Fleetworthy Solutions and Dan Rutherford with Summit Virtual CFO by Anders. Tune in above or by going to RoadSigns.ttnews.com.

Charles Mueller, scientist at Sandia National Laboratories, led an effort to develop ducted fuel injection, which provides a small duct a short distance from each spray produced by a diesel’s injector for better fuel/air mixing. The system reduces particulate to the point where EGR can be used to kill NOx in the cylinder, eliminating the SCR system. When running on oxygen-containing biofuels, the system may make it possible to meet NOx standards without exhaust gas recirculation while also reducing net-carbon emissions by 70%. Mueller is working with engine OEMs and low-net-carbon fuel providers to retrofit a heavy-duty engine with DFI and demonstrate the technology with a commercially available, low-net-carbon fuel and quickly move the technology closer to commercial applications.

Johnson described ClearFlame’s system that capitalizes on all the heat already available in a diesel engine to support the combustion of green fuels. Engines modified via ClearFlame’s system run on low-cetane fuels like ethanol that won’t ignite in ordinary diesels. The key is allowing heat ordinarily removed by the charge air and the EGR coolers to remain in the intake air. This greatly raises the temperature in the cylinder at the top of the compression stroke, and that is all that is necessary to ignite green fuels that don’t produce soot — meaning no DPF is needed. The engine’s ability to keep its exhaust hot allows a simple SCR system that will meet future, tighter NOx standards.

Alternative Fuels

At the Engine Research Center symposium at the University of Wisconsin last summer, Andre Boehman, professor of mechanical engineering and director of the W.E. Lay Automotive Laboratory, discussed low-net greenhouse gas fuel and engine technologies and brought attention to the diesel fuel known as dimethyl ether.

This illustration shows the top of the upcoming Cummins hydrogen engine to be built on the company's fuel-agnostic engine platform. (Cummins)

He noted that DME is an ideal diesel fuel with a cetane rating just above what present diesel has and, containing oxygen, it burns without smoke. It can easily be made out of renewable fuels like ethanol and many others, even agricultural byproducts, and its smokeless character means a high tolerance for EGR to combat NOx emissions. While it needs a pressurized tank, the pressure generated is much lower than even with propane, meaning far lower pressures than those needed for natural gas.

The fuel requires a different injection and combustion system from standard diesels as it evaporates very fast and has no natural lubricity, but likely can be adapted for use in engines with familiar injection and combustion systems.

OEMs such as Volvo have on-road tested DME before, while countries like Sweden have seen large-scale testing, where 10 heavy-duty commercial trucks drove more than 1.5 million kilometers powered by the fuel. One of the major challenges is engineering enough durability into DME injection systems, a process that may be augmented with exotic lubricity agents.

A notable alternative fuel, hydrogen, is 100% green and easily created from green electricity. Westport’s Johnson points out that fuel cells are most efficient at low loads, while piston engines are more efficient as loads increase. Thus, an ICE may be the ideal way to use hydrogen in commercial hauling, as opposed to passenger cars where engines cruise at low loads. He said Westport’s HPDI natural gas fuel system is easily adapted for retrofit to any internal combustion engine including one that runs on hydrogen. He argues that the company’s extensive experience supplying engines with gaseous fuels will give his company a leg up in the hydrogen internal combustion engine market.

Want more news? Listen to today's daily briefing above or go here for more info

Cummins is developing a spark-ignited, hydrogen engine. Jim Nebergall, general manager of Cummins Hydrogen Engine Business, told Transport Topics that the company’s hydrogen engine, another built on its fuel-agnostic platform, will be “a hybrid of our natural gas and diesel engines. It will be spark-ignited, yet direct injected.”

He explained that hydrogen creates such rapid flame travel that supplying fuel and air premixed in the intake manifold to the cylinders can allow flame to travel back into the manifold. Thus, a low-pressure fuel system a bit like diesel injection will supply fuel to the combustion chamber. The engine will resemble a diesel in that it will run very lean, with the extra air allowing about 20% more power.