Staff Reporter

Cummins, Daimler, Paccar Pick Site for Battery Plant Venture

[Stay on top of transportation news: Get TTNews in your inbox.]

Accelera by Cummins, Daimler Trucks & Buses US Holding and Paccar Inc. on Jan. 18 selected Marshall County, Miss., as the manufacturing site for their planned battery cell joint venture.

The engine maker and truck manufacturers’ project will localize battery cell production for commercial electric vehicles and is set to create more than 2,000 manufacturing jobs in northern Mississippi, with the option for expansion as demand grows, the partners said in a statement.

Production of battery cells at the 21-gigawatt-hour factory just across the Tennessee state line from Memphis is expected to begin in 2027.

Daimler Truck, Paccar and Accelera, Cummins’ zero-emission business launched last March, revealed the first details of the JV in September.

The partners believe the plant will “create the scale to deliver cost-effective and differentiated battery cell technology that supports the adoption of electric vehicles for medium- and heavy-duty commercial transportation.”

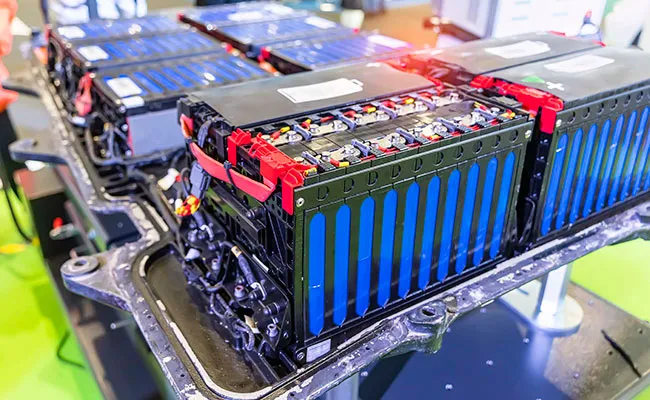

A lithium battery pack module. Paccar's Hergart said lithium-iron-phosphate batteries are ideal for commercial applications because of their durability, greater life cycle and lower costs compared with nickel, manganese and cobalt batteries. (kynny via Getty Images)

Accelera, Daimler Truck — parent company of Freightliner and Western Star owner Daimler Truck North America — and Paccar each own 30% of the venture, which will focus on lithium-iron-phosphate battery technology for commercial battery-electric trucks. China’s Eve Energy Co. will own the remaining 10% and contribute its battery cell design and manufacturing expertise.

“Localized battery cell production is an important component of delivering our customers — the fleets that keep America and the world moving — cost-effective options for decarbonizing their operations,” said John O’Leary, CEO of DTNA.

Hergart

During the recent CES 2024 in Las Vegas, Carl Hergart, Paccar senior director of global powertrain planning and agency, told reporters many factors are considered in the selection process, including tax incentives and supply chain logistics. However, he stressed that the end result would lead to manufacturing capacity that none of the partners could achieve individually.

Paccar is the parent of U.S.-based truck makers Kenworth Truck Co. and Peterbilt Motors Co.

Federal approval for the partnership is expected this year. Since Germany-based Daimler and China-based Eve Energy are headquartered outside the U.S., the partnership requires approval from the U.S. Department of the Treasury Committee on Foreign Investment in the United States. However, the partners have signed binding agreements and are aiming to finalize the agreement by year’s end, Hergart said.

He noted that LFP is ideal for commercial applications because of its durability, greater life cycle and lower costs compared with nickel, manganese and cobalt batteries.

Rich

“We want to have an incredibly durable, abuse-tolerant battery that goes for the life of the truck and that the customer can rely on,” Paccar Chief Technology Officer John Rich said during a media briefing on the sidelines of CES. “You have to ask yourself [how long] will that battery last. So chemistry has become very important.”

Just as important, Rich added, is building batteries specifically for trucks.

“There’s a lot of people making car batteries. We don’t make cars. We don’t make car parts,” he said. “We wanted a differentiated product that was unique to trucks. That was very, very important to us.”

🚛🚚 @AcceleraZero, #DaimlerTruck & #PACCAR select Mississippi for Battery Cell Production in the United States. 🔋⚡

The #JointVenture will localize #BatteryCell production for #CommercialVehicles

Press release: https://t.co/XywxBT9636 pic.twitter.com/8yZVMqMNDg — Daimler Truck AG (@DaimlerTruck) January 19, 2024

Hergart said Paccar hopes the initiative will make it easier for trucking companies to transition from diesel-powered trucks.

“It is hard to imagine a more exciting time in our industry,” he said. “As stewards of sustainability, we are steering the trucking industry to a zero-emissions future.”

For that future, supply security was paramount, “We had to know that we had access to the quantities we needed and wanted — of batteries — to enable our production plans and our changeover plans,” Rich said.

Paccar and DTNA brands were responsible for 69% of all U.S. Class 8 retail sales in 2023, according to Wards Intelligence data.

Want more news? Listen to today's daily briefing below or go here for more info: