Staff Reporter

Convoy Launches Backup, Spot Services for Drop-and-Hook

[Stay on top of transportation news: Get TTNews in your inbox.]

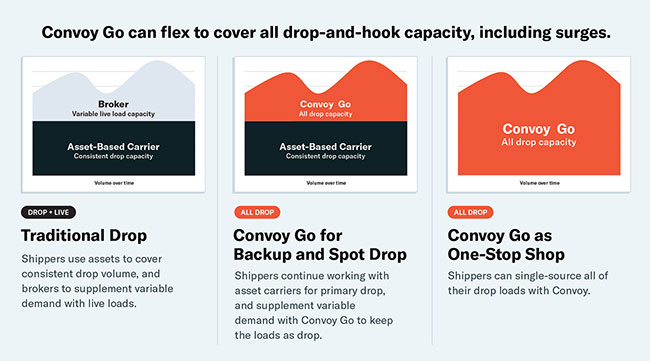

Convoy launched an automated drop-and-hook service for backup and spot freight to give shippers added flexibility for unexpected demand surges, the company announced May 19.

The Seattle-based digital freight network said this is the first time shippers have access to nationwide drop-and-hook coverage from the same provider across primary, backup and spot.

The new features represent the latest evolution to drop-and-hook service Convoy Go.

Ismail

“The way drop works in the market today across any player is that it requires freight to be highly predictable because you have to place trailers in the yard, and they have to be there ahead of time,” Chief Product Officer Ziad Ismail told Transport Topics.

“We now have systems that are figuring out where we’re going to have demand in the future and then we’re reallocating trailers, moving them around so that we can meet the surges in demand,” he added. “And so we’re now opening up drop for the first time to all the spots and backup shipments in the industry. It hasn’t been available before.”

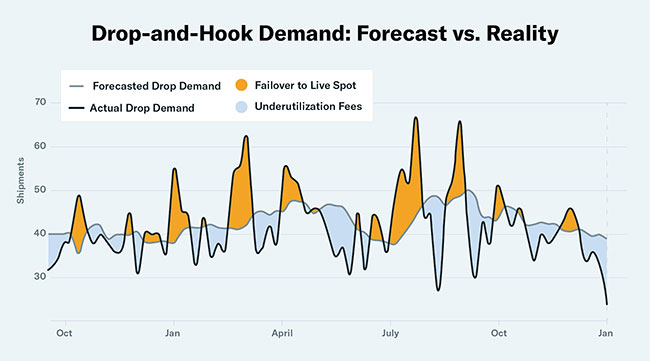

Ismail added drop shipments typically are constrained because shippers tell yards how many loads they expect in a given time period so they have those extra trailers available. But that means there isn’t much room for fluctuations. If a yard gets less than predicted, it will have excess capacity or not enough if it gets extra loads.

Convoy

The new systems instead analyze in real time the number of trailers in each yard and automatically reroutes them to help mitigate excess or insufficient trailer supply. Lead engineer Rylan Hawkins said the system was possible because Convoy has a massive network of carriers, remote management of smart trailers using real-time sensor data and automatic trailer repositioning using real-time optimization and machine learning.

“For all its benefits, the biggest problem with traditional drop-and-hook is simply that it’s inflexible,” Hawkins told TT. “When the market fluctuates, the demand fluctuates, shippers have no choice but to fall back to the spot market and live loading which, of course, creates logistical hassles, drives up costs to cover the loads and then puts shippers at risk of lower service quality.

“Convoy is taking a unique approach to drop that addresses those problems. We react automatically to market fluctuations so that shippers can flex their drops capacity, saving time and millions of dollars annually.”

Convoy

Drop-and-hook is when a driver drops a full container at a facility and then hooks the tractor to a pre-loaded one. Convoy said this method is preferable to shippers because of its efficiency. But such an approach can be inflexible since large trailer pools must be precisely matched with available drivers and tractors. The volatile supply chain conditions of the last year has made the practice difficult.

The new systems is intended to address the inherent limitations of drop-and-hook by leveraging technology such as predictive analytics and machine learning. Convoy estimates that shippers using it can save 9% of their annual freight spend on average. The service was in a pilot stage with select shippers since August.

Next-level technologies hold the potential to enhance safety and efficiency in transportation, but it takes a lot of work behind the scenes to advance these ideas from concept to reality. We talk with Christoph Mertz of the Robotics Institute at Carnegie Mellon and Huei Peng of the University of Michigan. Hear a snippet above, and get the full program by going to RoadSigns.TTNews.com.

“Convoy’s service is the first technology-driven drop-and-hook program of its kind,” Armstrong & Associates President Evan Armstrong said in a statement provided to TT. “Traditionally, carriers and 3PLs rely upon significant trailer pools and power unit assets to manually manage large-scale drop-and-hook or trailer interchange programs.

“Due to their cost and complexity, these operations tend to be limited to larger key customer accounts. Convoy’s service uses intelligent capacity management to dynamically manage fewer trailers to provide similar cost savings for a wider range of customers.”

Convoy noted an example of how machine learning models work is they can predict trailer demand several weeks in advance across hundreds of facilities nationwide. Those forecasts are combined with historical shipment data, GPS-based trailer locations, shipment assignments, inspection reports and driver locations to analyze billions of trailer routes every hour and select the best ones.

Want more news? Listen to today's daily briefing below or go here for more info: