Contributing Writer

Figuring Out Fan Drives

Art Trahan has nearly 241,000 commercial vehicles to maintain, so he doesn’t want to spend any unnecessary time thinking about fan drives. Thankfully for him, others are thinking about them for him.

Trahan is the senior manager assigned to national accounts for truck leasing and transportation provider Ryder System Inc. When purchasing vehicles, he has three choices when it comes to the mechanism that powers the fan that cools the engine: traditional on-off drives; two-speed drives, which can be used when full speed isn’t necessary; and variable-speed drives, which can run at different rpm depending on the application and need.

Many in the industry say variable-speed drives, which run only as fast as necessary, are increasingly popular. Variable drives can save on horsepower — a running fan can drain 25 hp on an engine running at 400 to 450 hp — and, therefore, save on fuel.

I don’t want fan drives to become something that I have to talk to a customer about.

Art Trahan, Ryder System Inc.

However, the more traditional on-off drive also is a popular choice because it’s simplest and cheapest, and for longhaul fleets, the fan rarely needs to operate, anyway.

Most of Ryder’s trucks have an on-off drive. Trahan said Ryder tells truck manufacturers how the vehicle will be used, generally accepts what the manufacturer recommends and rarely changes a drive after the truck is purchased.

“I don’t want fan drives to become something that I have to talk to a customer about,” Trahan said. “As long as the fan clutch doesn’t cause me any problems, we continue to go with what the manufacturers recommend. It has not been on my radar screen in some time.”

Jim Benson, engineering manager for North American applications at BorgWarner, said on-off drives are more familiar for Class 8 purchasers. For trucks traveling down an interstate at 62 mph, they remain a good option with low parasitics. The two-speed mechanism is attractive for often-stationary vehicles such as dump trucks. For BorgWarner products, it’s a direct retrofit for the on-off version.

But as demands for engine reliability and fuel economy increase, truck manufacturers are looking at making variable drives standard instead of optional, he said. Variable drives will become the dominant model, Benson said. “I think, in general, the industry is making a pretty decided move toward variable speed.”

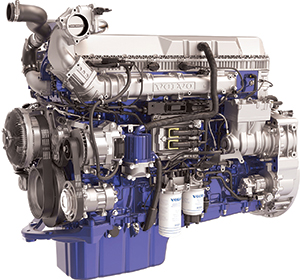

Volvo's D13 engine. Volvo is now standard with variable-speed drives. (Volvo)

John Moore, product marketing manager for powertrains at Volvo Trucks North America, said Volvo went standard with variable-speed drives in all models in 2017.

“We just want to save as much fuel as possible,” he said. “We want to be able to manipulate the fan to better match what it needs to be on to cool the engine.”

Executives with Freightliner and Mack agreed that variable drives are gaining in popularity.

Kelly Gedert, director of product marketing for Freightliner Trucks and Detroit Components, said more customers are using them. Moreover, “the expected demand for variable-speed clutches will continue to grow, with powertrain advancements supporting variable-speed technology.”

Roy Horton, director of product strategy for Mack Trucks, said Mack offers on-off and variable drives.

In the past the “vast majority” were on-off drives. “Today, variable-speed clutches are more prominent,” he said.

Duvin Sathyanath, product manager for control units at fan-drive maker Continental, agreed the trend is toward the variable drives because of their greater efficiency. That trend started with passenger cars. “All the innovations happen normally with the passenger car and then slowly, step by step, it goes to trucks and then buses,” he said.

And variable drives using viscous fluid rather than friction liners need less maintenance because friction liners sometimes need to be replaced, said Manish Virmani, vice president for global market development at Horton, another fan-drive supplier. It’s a big change, and the North American market is adapting to it.

Ease of maintenance and fuel economy were the reasons why P.A.M. Transportation Services’ entire order of 200 Peterbilts last year had variable drives, said Paul Pettit, vice president of maintenance.

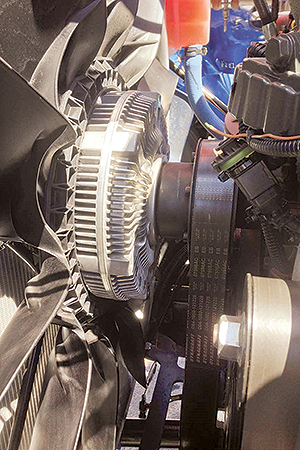

The Horton RCV250 fully variable fan drive. (Horton)

While the majority of the fleet still has on-off specs, Pettit said the company chose Horton variable drives because their architecture protected them from becoming collateral damage when a nearby belt breaks. As for fuel economy, the fleet is trying to measure if it made a difference, but it’s too soon to tell.

“We felt it was a good time to make the change to adopt the technology,” Pettit said.

P.A.M. Transportation ranks No. 68 on the Transport Topics Top 100 list of for-hire carriers in North America.

Not all manufacturers see the necessity of the variable option.

Navistar Inc.’s Jim Nachtman, heavy-duty product marketing director, said the on-off configuration is Navistar’s standard offering with over-the-road models, while two-speeds are an option.

His company’s testing has shown that on-offs are suitable for nearly all applications — certainly longhaul but also most regional ones.

For those applications, the fan drive rarely engages because the ram air — the airflow created by the vehicle’s forward movement — is enough to cool the engine.

Getting that air through the engine is critical, and a bit of a challenge.

Dave Hennessy, Horton’s vice president of research and development, said improving aerodynamics for fuel savings can reduce ram air. When that happens, the fan has to engage more often, which burns fuel.

“One of those challenges we face with the diesel-powered equipment is the desire for aerodynamics is directly in opposition to how much free cooling from ram air (occurs),” he said.

Navistar recommends the two-speed where the fan drive is cycling on and off frequently, such as in vocational applications with a lot of stop-and-go driving, and for operations in hotter climates.

Navistar doesn’t offer a variable drive, though it has in the past. Nachtman said on-offs offer lower cost, lighter weight, more simplicity and good uptime.

”We just don’t see the demand for it or the need for it, and really the on-off clutch for any over-the-road application just gives a better experience to the customer overall,” he said.

Truckload carrier USA Truck agrees. It uses only on-off drives for its 1,950 power units. Jeff Harris, vice president of maintenance, said his fleet considered using variable drives but ultimately has stuck with on-offs because of the difference in price. Harris also is general chairman of ATA’s Technology & Maintenance Council.

USA Truck, based in Van Buren, Ark., ranks No. 70 on the TT Top 100 list of for-hire carriers.

Other changes have been made to the fan itself.

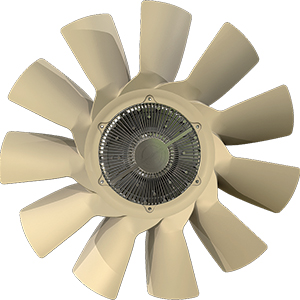

A BorgWarner fan. (BorgWarner)

BorgWarner’s research conducted with a truck manufacturer showed the traditional 11 blades weren’t necessary and that six would be sufficient to cool the vehicle, Benson said.

Reducing the number of blades allows more ram air to flow through the cooling system, Horton’s Virmani noted.

Navistar has been able to go from an 11-blade to a six-blade fan because the engine is operating more efficiently, Nachtman said.

More advancements are on the way.

BorgWarner’s Benson said next to come are smart products that merge the fan drive and transmission shifting into one control system, further optimizing the system. Fan drives could be tied with propulsion systems and adaptive cruise control.

“Bringing all these control systems together is offering trucks and fleets advantages that they didn’t have in the past,” he said.

And with electric trucks, even more changes are coming.

Fans will be electric rather than mechanical so they can work off the electric engines, as is being done with electric automobiles, said Horton’s Hennessy. Multiple fans will be needed because there are more elements to be cooled — batteries, motors, power electronics, heating and air units — and they are in different places. Together, they’ll probably drain less power than the one fan on diesel engines.

“You’re powering motors to drive the things there and you’re powering motors to cool it,” he said. “The challenges will be packaging size, things like power density of motors, noise depending on how fast you might have to spin them, how thick of heat exchangers might be needed.”

As for diesel trucks, the higher-cost variable drives may have an advantage concerning noise, maintenance and fuel consumption in some applications. That fuel advantage shrinks in longhaul routes where the drives engage infrequently.

“So is it worth it?” asked Horton’s Virmani. “That’s a question the industry is kind of battling with, and we’ll see over the next three to five years what they choose.”

“My bet is there’s still going to be a significant portion of the market that might just stay with the on-off and say it’s not worth changing.”