Targeting Tire Pressure

This story appears in the November 14 print edition of iTECH, a supplement to Transport Topics.

Many fleets are using technology that monitors tire pressure or automatically adds air as a way to improve fuel efficiency, extend tire life and prevent expensive roadside service calls, but these systems also could play an important role in the industry’s efforts to curb emissions in the years ahead.

Automatic tire inflation systems, or ATIS, and tire pressure monitoring systems, TPMS, are among the key emission-reduction technologies identified in the federal government’s Phase 2 greenhouse-gas rule for commercial trucks and trailers.

Those standards, set jointly by the Environmental Protection Agency and the National Highway Traffic Safety Administration, will be achieved through improved fuel economy — and preventing underinflated tires is part of that equation.

BEST OF NOVEMBER iTECH: More stories, columns

“We think the EPA was wise to acknowledge the validity of tire pressure as a component in fuel efficiency,” said Josh Carter, co-founder and CEO of Aperia Technologies, which provides an automating inflation system for tractor and trailer tires. “This is going to be a big change for the industry, for both fleets and suppliers alike. I’m optimistic that it will give fleets the confidence to move forward with some of the technologies.”

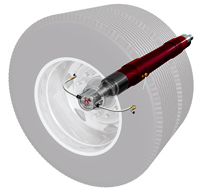

Hendrickson's Tiremaax Pro system

Hendrickson's Tiremaax Pro systemThe regulation imposes fuel-efficiency targets in four stages, starting with the first trailer requirements in 2018, followed by increasingly stringent standards for trucks and trailers in 2021, 2024 and 2027.

The final rule, announced Aug. 16, gives manufacturers credit for a 1.2% reduction in emissions and fuel consumption with ATIS and a 1% reduction with TPMS.

“ATIS does not require driver intervention like a TPMS system does, so a greater credit seems appropriate for ATIS,” said Tiona Campbell, controls program manager for trailer commercial vehicle systems at Hendrickson.

While the final Phase 2 GHG rule provides a 1% credit for TPMS, a version of the rule proposed in June 2015 did not include it at all. Arguments for and against the inclusion of TPMS centered on the fact that these systems monitor tire pressure but do not actively change it unless a driver or technician takes action based on that information.

“The agencies wanted to take the thinking away from the driver and place it into technologies, in this case an ATIS,” said Glen Kedzie, energy and environmental affairs counsel at American Trucking Associations. “We want carriers to be afforded the flexibility to spec equipment best-suited for their need.”

Jason Zaroor, CEO of Advantage PressurePro, said the addition of TPMS in the final rule “speaks volumes” concerning the demand in the market for the technology.

“Numerous studies have proven TPMS to be an effective tool in both adding safety and reducing emissions,” he said.

James Sharkey, senior director of global sales and marketing at Pressure Systems International, described the 1.2% credit for ATIS as “very conservative.”

Depending on a fleet’s operations, ATIS typically will deliver a 2% or higher improvement in fuel economy, he said.

Nonetheless, suppliers said they expect the regulation to accelerate the adoption of tire-pressure technologies in trucking.

In general, truck and trailer makers will be able to select from a menu of technologies to reach the Phase 2 GHG targets, including engine refinements, aerodynamic enhancements and low-rolling-resistance tires, as well as ATIS and TPMS. But for non-box trailers such as flatbeds, tankers and container chassis, the rule creates design standards that require the installation of ATIS or TPMS rather than efficiency goals.

While regulation has raised interest in tire-pressure systems from an emissions standpoint, many fleets are implementing these technologies today to prevent tire failures and enhance efficiency.

RRR Transportation, a refrigerated carrier that hauls fresh produce, uses the Meritor Tire Inflation System by PSI.

“The benefits for us from the PSI ATIS are fuel economy, tire wear, safety and reduced road service calls,” said Rodney Franklin, director of maintenance at RRR, based in Calhoun, Georgia. “If a tire picks up a nail, the system makes the driver aware that there is a problem. In most cases when a puncture occurs, the PSI system will keep up with the loss of air pressure until the driver can get to a place where the tire can be serviced.”

Avoiding road calls can be particularly important for the carrier because its trucks travel through isolated areas at times.

“If you have to bring in road service to a remote location that is hundreds of miles away from anything, it can be very expensive,” Franklin said. “Plus, refrigerated freight is time sensitive, so there is the danger of losing the freight.”

One restriction on PSI’s ATIS is that it can be used only on trailer tires. This also holds true for ATIS systems from Hendrickson and Stemco. The air used to inflate tires comes from existing air tanks and is routed through the hollow trailer axle out to the tires.

“Adapting an ATIS to a trailer axle is easier than a drive axle,” PSI’s Sharkey said. “Since drive axles have gearing inside the housing, it increases the complexity of routing the air to the wheel ends, which also increases cost.”

However, Aperia’s Halo Tire Inflator, introduced in 2014, uses a different design that allows the devices to be used on tractor tires as well as trailer tires.

“Unlike the other inflation systems on the market, the Halo system doesn’t require a centralized, onboard air compression system,” Carter said. “Our Halo ATIS works in a way that is similar to a self-winding watch. There’s a pendulum hanging inside the device, and as the truck goes down the road, the Halo device is spinning right along with the tire. The relative motion inside the device is utilized to create pumping action.”

Gulick Trucking has installed Halo devices on about 30 of its tractors and is considering adding the systems on all of its new orders next year, said Brian Patrick, a safety manager at the Vancouver, Washington-based fleet.

“It’s nice to have something right there that starts putting air in when the tire needs it,” he said.

Although Aperia may currently have the only ATIS that can be used on tractor tires, PSI is working on an externally mounted system for trucks’ drive axles.

“While the development is progressing, we are not yet at a point to announce its commercial availability,” PSI’s Sharkey said.

Although ATIS technology focuses on adding air to underinflated tires, Hendrickson’s Tiremaax Pro is capable of inflating and deflating tires.

“All check valves or wheel valves are open to allow air to flow in both directions with the same pressure across all tire positions,” Campbell said.

Meanwhile, Stemco offers a TPMS product and its Aeris ATIS system.

One of the options for Aeris is SmartSense, which uses “enhanced electronic airflow detection technology to distinguish between minor and major air leaks,” said Prashanth Kamath, segment business leader for tire and mileage solutions at Stemco.

“The Aeris system can inflate leaking tires to enable a driver to get to a safe location in the event of a slow leak,” he said. “An additional safety feature is a pressure protection valve to protect the integrity of the air brake system in the case of a major and continuous air leak.”

Meanwhile, PSI offers ThermAlert, which is an early-warning notification for overheated wheel ends.

“Wheel ends can overheat for various reasons, such as a bad wheel bearing adjustment, a failed or improperly installed seal, insufficient lube or a bad bearing,” Sharkey said. “As a wheel end starts to deteriorate, it will begin to overheat. If no action is taken, the results can be catastrophic.”

If this happens, the system alerts the driver through a warning light on the driver’s side of the trailer. If the heat reaches a certain temperature threshold, the ThermAlert plug will melt in a way similar to how a fire sprinkler system is activated. When the plug melts, it lets air out of the axle through the hub cap vent, illuminating the indicator light and creating a loud whistling sound.

Having been alerted to the problem, the driver can then have the wheel end repaired right there before more extensive damage occurs, Sharkey said.

“There are probably a couple of times a year when this saves our bacon,” RRR’s Franklin said. “If you have a hub burn up, that’s bad enough, but it could be worse. The trailer and the load could burn or you could have a fatal accident, so it’s well worth it in our estimation.”

Tire-pressure monitoring systems, such as those from Advantage PressurePro, Doran Manufacturing, Bendix Commercial Vehicle Systems and Wabco Holdings, provide technology that can monitor the tires on tractors and trailers and send pressure and temperature data to an in-cab display.

Drivers must respond to that information and inflate the tires when needed, and if they do, the benefits can be dramatic.

“I estimate that we have had around a 90% decrease in tire-related road calls after we started using the Bendix TPMS,” said Barry Parham, maintenance director for Performance Trucking, based in Lawrenceville, Georgia. “Also, we’ve seen a 40% increase in tire life on tractor tires.”

Low air pressure increases the risk of tire failure, Parham said.

“Tires are designed to flex at a certain point. If the air pressure is low, the tire flexes at a different place where it’s not designed to flex,” he said. “It fails at the sidewall of the tire. If you have a blowout of this type, it’s likely that the tire pressure was too low.”

A new feature for Bendix’s SmarTire system provides alerts when dual tires have mismatched air pressures, which can cause irregular and rapid wear on both tires.

Another player in the TPMS market is Wabco, which offers its Integrated Vehicle Tire Monitoring System.

Tire-pressure technology not only improves efficiency but also can make highways safer, said Jon Morrison, president of Wabco’s Americas business unit.

“NHTSA reports that defective tires are the leading cause of crashes involving commercial vehicles,” he said. “Incorrect tire pressure is part of this problem and can certainly pose risks.”

With timely alerts on low tire pressure, drivers can address the issue immediately and avoid potentially erratic vehicle handling, reduce extended braking distances and prevent blowouts, Morrison said.

The TPMS data viewed in-cab by the drivers also can be transmitted to fleet offices through mobile communications systems.

Having access to the TPMS data allows fleets to not only remedy tire problems when they occur but to start recognizing tire performance trends, said Vanessa Hargrave, chief operating officer at Advantage PressurePro.

“This is a game changer as the constant flow of information, and the analysis of it, can really help fleets take their tire maintenance programs from reactive to proactive,” she said.

For drop-and-hook applications, where one truck could pull any trailer at a given time, Doran’s TPMS uses a trailer transceiver to wirelessly communicate trailer tire pressure and temperature data from the trailer to a monitor in the truck.

Those transceivers and the company’s SmartLink tablet are designed to make air checks more accurate and efficient, said Lee Demis, director of business development at Doran.

When used together, technicians can upload the last reported tire pressure and temperature information for all trailer tires at the same time, he said.

“This data is date- and time-stamped, and can be uploaded to tire and maintenance software for accurate record keeping,” Demis said. “Technology is eliminating the need to be on your hands and knees, manually gauging tires in the yard.”

Jon Intagliata, TPMS product manager at Bendix, also emphasized the opportunity for fleets to improve operations with the aid of TPMS information.

“We feel that the proliferation of telematics systems and the resulting ability to send the TPMS data to the back office will result in better tire maintenance practices, since fleet managers will see inflation issues and be able to ensure they are addressed by either the driver or maintenance personnel,” Intagliata said. “Studies have shown the positive effects of TPMS, and Bendix is glad to see the EPA has recognized these benefits.” ³