5 Things Fleet Pros Know About Smoke

Diagnostic leak detection technology — sometimes referred to in the field as smoke testing or using a smoke machine — is being used by the most advanced fleets as a surprising solution to otherwise time-consuming problems. Take a look at the top 5 below!

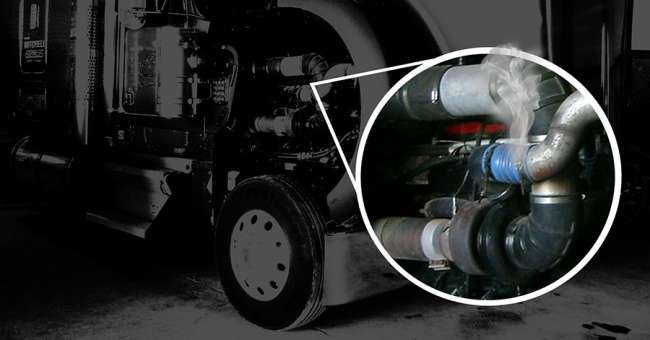

1 High pressure smoke is the ONLY way to simulate the boost of a running engine.

73% of upstream component faults are so small they only open up under the pressure of a running engine. The only way to pinpoint those failed components – and avoid parts darts and comebacks – is a high pressure smoke machine. The machine simulates the boost of a running engine so you can safely test with the engine off. In under 15 minutes the faulty component is pinpoint clear with 100% certainty.

2 More and more transport vehicles are CARS.

With the rise of a delivery economy, fleet managers are called to maintain and repair a wider range of vehicles, from Class 8 trucks to hybrid passenger cars, making standardizing maintenance procedures more difficult. Using smoke technology makes finding performance-killing component leaks simple, so even the least experienced tech on the team can do diagnostics, freeing up more experienced technicians to make repairs.

3 Three letters: D P F

DPF systems can be troublesome to maintain and a bear to repair. 89% of trucks tested had upstream component leaks that are the root cause of DPF problems like frequent forced regeneration, filter over-clogging, and lower fuel economy. Leaks are caused by road wear but can also be introduced when technicians re-install diesel particulate filters after routine cleaning. Running a 10 minute smoke test after filter re-installation is the only way to insure that there are no little leaks that are going to cause big problems.

4 Four letters: E V A P

Using a low pressure smoke machine, .5 PSI or less, to find EVAP leaks is a big time saver. Faults can cause the engine management system to throw on more fuel and cause performance issues without always triggering a check engine light. Using a smoke machine makes quick work with 100% certainty the problem is fixed.

5 Fuel costs

A leak in a heavy duty, boosted, or naturally aspirated engine will lower fuel economy. By using diagnostic leak detection in regular PM, those leaks can be quickly found and repaired, reliably improving fuel numbers across the fleet. Using a smoke machine on your fleet vehicles will not only improve fuel economy, it will lower maintenance costs, cut downtime, and increase driver uptime.

You can see a full range of made-in-America quality smoke machines from the industry leader in diagnostic leak detection at www.redlinedetection.com. Their technical experts are available to answer your questions and help you use the tool at (714) 451-1411.

About Company – Redline Detection LLC, headquartered in Orange, Calif., develops and manufactures the world’s best-selling diagnostic leak detection equipment. From the world’s leading OEMs to individual technicians, Redline Detection has built a global fan base for its professional grade custom diagnostic solutions, as well as for its ability to increase the bottom line. To learn more about Redline Detection and its award-winning products, please visit www.redlinedetection.com