Volvo’s 2024 VNL: Surprising Electrical, Mechanical Changes

[Find the latest in equipment & maintenance: Explore this quarter's issue of Calibrate]

As you know, there’s a synergy among driver comfort, simplicity of maintenance, better fuel economy and fleet operating ratio. There are a number of significant changes in support of these areas in Volvo’s 2024 VNL. The new truck has radically improved aerodynamics, including an overall wedge shape easily seen from above. Those improvements include an elaborate duct system to channel air through the engine compartment for cooling while reducing resistance to airflow.

MORE ON THE VOLVO VNL: Showcased at TMC | Early look at redesign | Details on engine updates | Redesign unveiilng

Internal changes include electrical system and engine mechanical advancements. By far the largest change — the 24-volt electrical system — provides a greater advantage in VNLs with sleepers, in which a revolutionary battery-powered integrated parking cooler now will allow a driver to sleep in silent comfort (without idling) for eight hours.

Twenty-four-volt electrical “lowers current demand” throughout the system, says Duane Tegels, product marketing manager of powertrain for Volvo Trucks North America. That means not only all the wiring harnesses, but also the entirely electrical parking AC compressor, the starter and even the alternator.

Baxter

Consider what happens when a 1 horsepower electrical sleeper AC compressor is powered by 24 volts rather than 12. The amperage drops from 60.666 to 30.83. The reduction in resistance to current flow and the heat it creates in the compressor, which must be removed by the AC system, makes the compressor and the entire system significantly more efficient. This enhances its ability to operate for long periods on stored energy. The new starter looks tiny because, as Tegels said, its armature can be much smaller, reducing weight. Amps for a 100 hp starter would drop from more than 6,100 to fewer than 3,100 at 24 volts. That means less heat during prolonged cranking.

Nearly silent overnight sleeper air conditioning comes via the chassis-mounted (as opposed to cab-mounted), electrical compressor and two electric condenser fans mounted in front of the radiator.

Volvo eases concerns about battery replacement, providing 24-volt battery power by wiring standard 12-volt batteries in series, rather than using relatively rare 24-volt batteries. “Day cabs will be standard with flooded lead-acid batteries, and sleepers will be standard with AGM (absorbed glass mat) batteries,” Tegels said, which means terrific energy storage for hotel loads. AGM batteries are deep-cycle units that can be run down to 50% of charge without undue wear while maintaining plenty of grunt for engine starting. Cranking can be augmented via an optional ultra-capacitor starting system. During sleeper AC operation, the battery protection system will start the diesel and charge the batteries back up should current usage drop voltage to levels that would shorten battery life or risk a no-start. Jump starting can still be easily performed by strategically connecting to “specific battery posts” in a process Tegels called “jump charging” so the batteries can be charged from a 12-volt source to get a truck back up and running.

Various battery and 24-volt alternator options are offered, with up to 6 AGM batteries being available, along with both brush-type and brushless 24-volt alternators up to 160 amps. Since a 24-volt alternator takes no more torque to turn than a 12-volt design, the alternator will be driven by the same serpentine belt system. Twenty-four-volt alternators and starters will be in stock at Volvo dealers by the start of production in April.

More Q2 Calibrate

►Work Continues on Establishing PC-12 Oil Category

►Freeze: Balancing Out the Future

►Fleet Concerns Remain Dynamic for 2024, TMC Data Says

►Baxter: Volvo’s 2024 VNL: Surprising Electrical, Mechanical Changes

Explore the Issue!

During on-road operation, the cab and sleeper will be cooled by a standard AC system with belt-driven compressor, and the engine cooling system will have the standard belt-driven fan. Compatibility with a 12-volt world won’t be a problem.

“All vehicle lighting is now 24-volt LED-based, but there are still 12-volt components in the trucks,” Tegels said. “For those specific components, voltage converters provide the required 12-volt supply. All DC power supplies inside the cab are either 12-volt or USB-C. If the truck is equipped with shore power or an inverter, 120V AC power is also provided within the sleeper. We also secure 12-volt interfaces for body builders and trailer connections.”

Powertrain improvements drivers and fleet managers will love also are abundant in the 2024 VNL. Maximum power and torque have been enhanced. The top rating last year was 455 horsepower with 1,850 pound-feet of torque, but there are now a 500 hp, 1,850 pound-feet torque rating and a 500 hp,1,950 pound-feet torque rating.

Volvo figured out how to lengthen the engine’s connecting rods, a change that reduces piston side-thrust and friction. The trick was a shorter piston with the pin mounted closer to the crown. The crown itself now has seven waves rather than six, and this means a 7-hole injector rather than a 6-hole design. The injector also incorporates a smaller needle and valve seat at the bottom, which means faster response and more consistent atomization, reducing during cold starts.

Volvo's Johan Agebrand discusses the Volvo VNL at TMC 2024. (John Sommers II for Transport Topics)

Tegels noted the implementation of seven-wave injectors represents a pivotal development, facilitating finer fuel spray patterns and precise control over the fuel-injection process.

“This refinement ultimately fosters an enhanced fuel-to-air mixture, promoting a more complete combustion process,” he explained. “This optimized combustion results in a higher combustion efficiency, leading to the combustion of a greater proportion of fuel and a notable reduction in the formation of hydrocarbons that contribute to soot.”

This statement is supported by the work of noted researcher Dr. Dennis Siebers and his team at Sandia Laboratories. Their engine-combustion research revealed that one of the largest effects of advanced diesel injection systems is smaller nozzle holes and resulting smaller-diameter sprays, characteristics of the 7-hole injector. Smaller sprays grab more air as they stream out of the nozzle, helping greatly to reduce soot, which results from air deprivation. Tegels states that the seven pockets formed by the increased number of waves also enhance turbulence.

Added to these advancements is a smaller-diameter turbocharger and turbo-compounding turbine, which means faster spooling up. Enhanced insulation of these parts keeps the heat that actually drives the turbo and turbine in the system, further improving performance.

A new emissions after-treatment system combines the DPF and SCR systems into a single unit that retains exhaust heat. (Volvo)

As a result of the combustion enhancements, the piston crown is now subjected to less heat, especially less uneven heating. The resulting reduction in heat stress on the piston allows the increase in power and torque, helps produce the overall improvement of as much as 10% in fuel economy and puts less stress on the engine oil.

The longest Volvo-approved oil change interval was 75,000 miles when getting 7.5 mpg, but it is now 90,000 for trucks getting 8.5 mpg. Parasitic loads are reduced by the variable-vane oil pump, which adjusts oil flow for the conditions, pumping a slightly smaller volume of oil under low-load conditions.

The new powertrain provides 30% faster shifts, a feature I noticed in a test drive and one drivers will love because of faster acceleration. How has this been accomplished? Clutch throw has been reduced from 4 mm to 2 mm, and a more powerful countershaft brake enables faster synchronization of gear speeds and quicker engagement of the next gear. Tegels said the clutch disengages briefly to allow the countershaft brake to provide immediate engagement of the next gear, while the engine slows to nearly the right rpm, if necessary with the assistance of the newly enhanced engine brake. The shift is finalized as the clutch handles any remaining difference between engine and transmission input shaft speeds, primarily with a slight compression of the damper springs and little or no slippage.

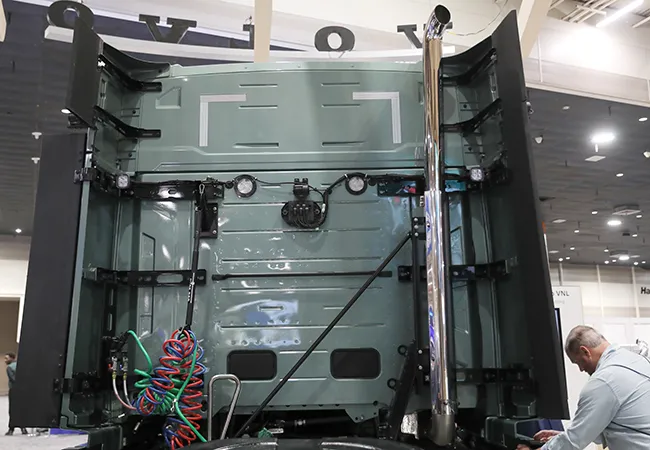

A back-of-the-cab view of the all-new Volvo VNL. (John Sommers II for Transport Topics)

When fueling stops during an upshift, turbo rpm will gradually decay. So, faster shifts mean less turbo lag once the system gets back on the throttle. Thus the truck’s faster acceleration also results from quicker engine response after a shift. The quicker, more consistent acceleration is very apparent behind the wheel. And, quicker shifts enhance fuel economy because when an engine is turning over without driving the truck, energy is wasted.

The fuel economy I-torque specification features a super-fast 2.15:1 rear axle ratio. Inspired by input from Joel Morrow, an owner-operator and owner of Alpha Drivers Consulting in Cleveland, it uses the D13 TC. On level roads in top gear, the engine rpm is only 960 at 65 mph, giving great performance via this powerplant’s 900-rpm torque peak. The low-rpm grunt cooperates with transmission software that provides a downshift as soon as needed for hill climbing or acceleration. The transmission provided with this specification is a 13-speed, adding a crawler gear for startability and slow backing into the loading dock in spite of the ultra-fast axle ratio.

Want more news? Listen to today's daily briefing below or go here for more info: