Maxion, Denso, Webb Wheel, Eaton, Meritor Unveil New Products at Heavy Duty Aftermarket Show

Maxion, Denso, Webb Wheel, Eaton and Meritor were among the companies who introduced new products or expanded product lines during the Heavy Duty Aftermarket Week trade show that wrapped up Jan. 26 in Las Vegas.

Among the highlights:

Maxion Wheels

Maxion

Maxion Maxion Wheels announced that it expanded its North American Commercial Vehicle product offering by adding forged aluminum truck wheels. It developed the four-wheel product line in response to the market’s growing need for lighter vehicles as a way to reduce fuel consumption and greenhouse-gas emissions, according to the company.

The new 22.5x8.25 aluminum CV wheel weighs 45 pounds.

“By adding forged aluminum to our product mix, our steel wheel commercial vehicle customers now have a one-stop alternative for their wheel needs,” Donald Polk, president of Maxion Wheels, Americas, said in a statement. “Our forged aluminum truck wheels are built for today’s toughest road conditions.”

Fleets operating in North America can buy the wheels through aftermarket channels starting this spring, with an initial rollout of the 22.5x8.25. The wheels also will be available in sizes 24.5x8.25, 17.5x6.75 and 22.5x14. The aluminum wheels, which are compatible and interchangeable with current market offerings, were designed to exceed industry standards, Maxion Wheels said.

The company, which says it’s “the world’s largest wheel manufacturer,” produces nearly 60 million wheels a year.

Denso

Denso Products and Services Americas Inc. has partnered with Clean Diesel Technologies Inc., or CDTi, a global manufacturer of vehicle emissions control systems, to launch a line of aftermarket emissions control products for heavy-duty trucks and equipment.

The PowerEdge diesel aftertreatment line is distributed by Denso and manufactured by CDTi. The products include diesel particulate filters and diesel oxidation catalysts, or DOCs.

These replacement DPFs and DOCs match or exceed the emissions control performance and benefits of original equipment manufacturer replacement units when installed in 2007 and newer heavy-duty diesel equipment, according to Denso.

“CDTi is a clean-tech company that shares our commitment to product reliability and durability, rigorous safety and performance standards, innovation, customer service and environmental stewardship,” Frank Jenkins, senior manager of Denso’s Heavy Duty Marketing Group, said in a statement.

The all-makes original equipment replacement program features 60 DPF part numbers covering more than 260 original equipment-quality products and seven DOC part numbers for heavy-duty on-road and off-road trucks and equipment, Denso said.

Features include high-grade stainless steel and other materials that help resist corrosion and prevent failures and CDTi’s patented coatings that increase catalyzation and regeneration efficiency, among others.

All part numbers meet U.S. Environmental Protection Agency emissions control regulations and can be bought and installed in 49 U.S. states and Canada.

Based in Long Beach and Murrieta, California, Denso Products and Services Americas is an affiliate of Denso Corp., a Japan-based global automotive supplier.

Webb Wheel

Webb Wheel

Webb Wheel Webb Wheel Products Inc. introduced a new brake drum for use in trailer applications, which it called the newest addition to its wheel-end portfolio.

Many trailers are running with side skirts that improve aerodynamics, but over-the-road data suggest they also can reduce crosswind and straight line air flow below the trailer, according to the company. This air flow reduction results in a 41% increase in brake temperatures, causing less-effective braking and increased brake drum and lining wear, Webb said.

However, its lighter, cooler Webb trailer drum with patented Webb Cool Running Technology vents was engineered for trailer axles with 20,000-pound capacity, Webb Wheel said.

“The push to increase trailer aerodynamics has created opportunities for trailer component suppliers to design products that recognize how these new technologies can change overall trailer functions,” Johnathon Capps, vice president of engineering, said in a statement.

The Webb 66764F brake drum vents increase air flow for heat transfer efficiency and cooler trailer wheel-end operating temperatures, managing heat 10% better than similar-weight brake drums, the company said. The brake drum offers the lowest weight in its class at 99 pounds, Webb said.

Webb Wheel Products also manufactures hubs and rotors for medium- and heavy-duty trucks, trailers and buses. Based in Cullman, Alabama, it’s a Marmon Highway Technologies-Berkshire Hathaway company.

Eaton

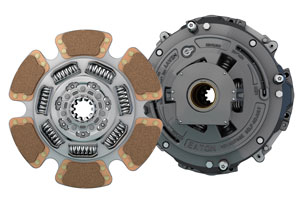

Eaton

Eaton Power management company Eaton is set to release upgrades to its Advantage Series of heavy-duty clutches with several design changes to improve durability, reduce vibrations and allow smooth shifting across torque ratings up to 2,250 pound-feet.

The changes for the Eaton Advantage Self-Adjust and Eaton Easy Pedal Advantage clutches also include a reduction in part numbers to 28 from 41 by combining several earlier models into one. The line will continue to cover all commercial heavy-duty truck applications.

Improvements include a new system that prolongs clutch life by eliminating “lug fatigue” that over time could lead to failures. The design also eliminates noisy rattle associated with the prior lug design, Eaton said.

The clutches also feature a damper technology that enables downspeeding at all torque ratings up to 1,850 pound-feet. This technology absorbs engine vibrations to prevent driveline damage and is standard on all clutches, Eaton said.

Another upgrade includes a second wear tab indicator that’s been added to the Advantage Self-Adjust model, providing maintenance professionals better access during visual inspections.

Original equipment manufacturer production is scheduled to begin in the second quarter, with aftermarket production starting in the third quarter, Eaton said.

“The improvements we have made support the changing requirements of contemporary diesel engines and powertrains, including downspeeding designs,” Ben Karrer, global product strategy manager for Eaton, said in a statement, adding that this line of clutches is “the smoothest and most durable ever developed by Eaton.”

Meritor

Meritor announced that the FastSet King Pin Kit product line has been expanded to offer 45 no-ream kits that provide fleets with a faster solution for aftermarket replacement.

With the kit, king pin bushings don’t need to be reamed after they are installed into the steering knuckle, which saves labor, time and costs, Meritor said. Customers can install spiral bushings by hand.

“Meritor FastSet is now available for all popular axle applications, including Meritor, Dana, Eaton, Spicer, Mack, Volvo, Chevrolet, GMC, Isuzu and Axle Alliance,” said Joe Ghering, product manager, Steering and Suspension, Aftermarket for Meritor, in a statement. “With fleets looking for ways to increase vehicle uptime, FastSet eliminates the need for reamers, special tools and presses when replacing king pins.”

The Troy, Michigan-based Meritor Inc. is a global supplier of drivetrain, mobility, braking and aftermarket products for commercial vehicle and industrial markets.