Staff Reporter

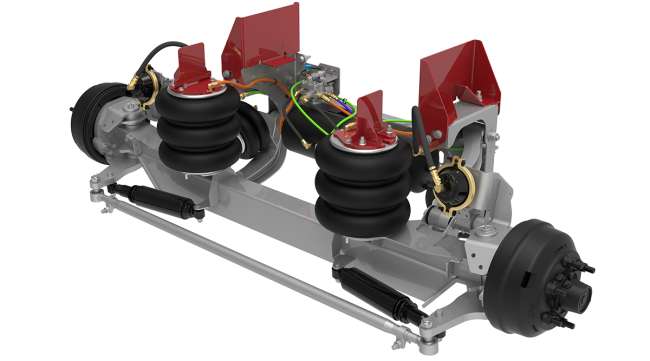

Link Manufacturing Unveils Smart Auxiliary Suspension System

[Stay on top of transportation news: Get TTNews in your inbox.]

CLEVELAND — Link Manufacturing Ltd. unveiled its intelligent auxiliary suspension system Sept. 12 at American Trucking Associations’ Technology & Maintenance Council’s Fall Meeting & Transportation Technology Exhibition.

Based in Sioux Center, Iowa, Link manufactures suspensions for commercial vehicles and equipment.

Developed with the company’s proprietary Road Optimized Innovations technology, the Auxiliary Suspension is designed to sense and maintain optimal tire-to-ground pressure. The system is meant to reduce tire wear and maximize fuel mileage.

Brian Kujala, vice president of business development for Link, said traditional auxiliary suspension systems can require some guesswork, even for experienced vehicle operators.

Fleet managers find that healthy, happy drivers are key to business success. Stephen Kane of Rolling Strong says driver health starts with “being vulnerable enough to listen to somebody that knows about health.” Hear a snippet above, and get the full program by going to RoadSigns.TTNews.com.

“Auxiliary suspensions today are not so smart,” Kujala said during the press conference. “Most hauling scenarios rely on operators to determine whether a load is properly handled by the vehicle’s primary suspension system or whether its auxiliary axles should be deployed.

“When a vehicle is either empty or fully loaded, the choices related to auxiliary axle are intuitive, but variable payload densities and the need for partial load flexibility can make for tricky choices and lead to far-reaching consequences.”

The ROI Auxiliary Suspension will be commercially available in 2022. In terms of applications, the suspension can be used in heavy-duty, cement, dump or refuse trucks.

The system also is equipped with traction response technology, which is meant to help drivers operating in snow or mud.

Brian Kujala, vice president of business development for Link, says the suspension can be used in heavy-duty, cement, dump or refuse trucks. (John Sommers II for Transport Topics)

Besides improving safety, Kujala noted the suspension can lead to faster training and onboarding, which are important factors considering the industrywide truck driver shortage. ATA estimated the trucking industry needed an additional 60,800 truckers in 2018, a shortfall that is expected to grow to 160,000 drivers by 2028 unless recruiting efforts improve.

“With Link’s intelligent, load-balancing auxiliary suspension system, the guesswork is removed so even inexperienced drivers can maintain maximum traction without overloading the axle,” Kujala said. “Fleets will be able to get new drivers trained and working in less time.”

In addition to the new suspension system, Kujala discussed some of the company’s expansion efforts that have taken place during the COVID-19 pandemic. Link representatives broke ground on a manufacturing and training facility in Sioux Center in March. The plant expansion, designed to increase manufacturing capacity and accommodate additional staff, is expected to be completed in the fourth quarter.

Want more news? Listen to today's daily briefing below or go here for more info: