Fuel Cells Gain Momentum as Range Extenders for Electric Trucks

When Nikola Motor Co. President Trevor Milton pulled the wraps off the Nikola One prototype Class 8 truck last year and announced it would have a hydrogen fuel-cell power plant, it seemed a radical approach at the time. But since then, the concept of using fuel cells as range extenders on battery-equipped heavy-duty trucks has gained significant traction.

Fuel cells, which generate electricity during the chemical process of uniting hydrogen and oxygen, aren’t a new technology. In fact, fuel cells provided the electrical power needed by the Apollo astronauts traveling to and landing on the moon in the late 1960s and early ’70s.

Now, suppliers and researchers are looking at ways to apply this technology to trucking.

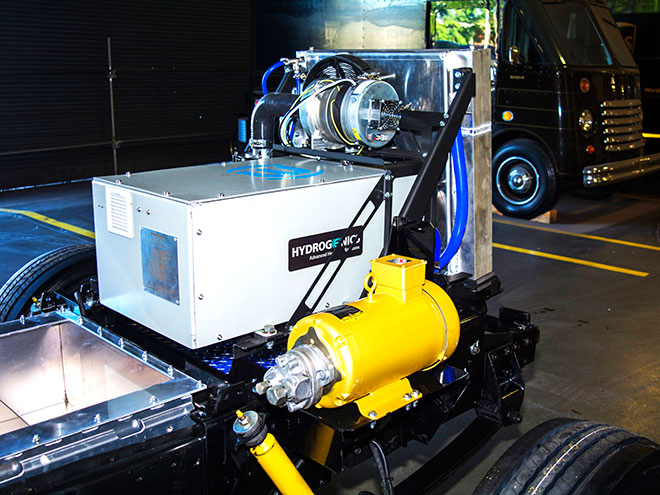

At the 2017 Fuel Cell Seminar & Energy Exposition, held Nov. 7-9 in Long Beach, Calif., the center of attraction was a Navistar International ProStar equipped with TransPower’s battery-electric system with a range-extending fuel cell by Hydrogenics Corp.

Similar to the Nikola One powertrain, the TransPower-converted ProStar carries the highly compressed hydrogen fuel in steel gas cylinders.

TransPower

TransPower Vice President of Business Development Joshua Goldman said the truck was created for the Port of Long Beach and put into service in the week before the Long Beach seminar.

The byproduct of the hydrogen fuel-cell system is pure water, which drains off the zero-emission power unit. The generated electricity is used to replenish the on-board lithium-ion vehicle batteries that power the electric motors that drive the truck.

“It ran faultlessly but we had one complaint,” Goldman said. The receiver of the shipment “asked if we would shut off the fuel cell inside the plant as it was making a puddle on the floor.”

The fuel-cell-equipped truck’s performance is identical to that of the six battery-only trucks that TransPower and the port have already put into service, Goldman said. The difference with the latest fuel-cell demonstration truck, however, is that it carries fewer of the heavy and expensive battery packs because its range is determined not by how much charge can be stored in the lithium-ion batteries, but how much hydrogen is packed into the vehicle tanks. On the demonstration truck, the range is 50 miles on battery and 200 miles when the fuel-cell range extender is running.

“With fuel cells, you can size the energy conversion device — the fuel-cell stack — to meet the power demands and simply size the hydrogen storage to be appropriate for the amount of energy you need,” said Jack Brouwer, associate professor of mechanical and aerospace engineering and associate director of the National Fuel Cell Research Center and Advanced Power and Energy Program at the University of California, Irvine. As a result, it’s possible to make “a totally zero-emissions truck” that can haul a big payload over a reasonable distance without adding so much weight, Brouwer said. This type of separate power and energy sizing of the truck’s fuel cell “is not possible with batteries alone,” he added.

Such is the case with a demonstration Kenworth T660 that Toyota outfitted with two of the fuel-cell stacks that power its Mirai hydrogen car. The truck program is called Project Portal.

“This is a proof of concept, and we really want to show that the powertrain works,” said Tak Yokoo, senior executive engineer at Toyota. “It should be capable for all truck operations.”

Toyota engineers packed the power stacks and batteries into a dromedary box on the frame behind the cab. The truck relies on a small battery and enough liquefied hydrogen to haul an 80,000-pound truck 200 miles. Toyota is demonstrating the technology at the ports of Long Beach and Los Angeles, where hydrogen is available.

Meanwhile, fleets also will be testing the recently unveiled Tesla Semi, which, unlike the Nikola One, is battery-only technology.

In early November, the ports of Long Beach and Los Angeles adopted an updated Clean Air Action Plan. One of its largest goals is to move all Class 8 trucks to zero or near-zero emissions by 2035.

“These demonstrations are very important for us,” said Rick Cameron, managing director of planning and environmental affairs for the Port of Long Beach. “One of the commitments is within the next few years to deploy a demonstration fleet of 50 to 100 zero-emission trucks.”

“We are seeing a variety of technologies,” he said, noting that even the battery-electrics have varying duty cycles. “We see them as being the short-haul trucks — we have a lot of cargo that is destined to stay within 10 miles of the port complex,” Cameron said. “That’s where we’re going to be extending our demonstration to see how certain trucks can meet certain shorter hauls rather than the longer hauls in the Southern California region.”

However, a large percentage of cargo needs to travel via truck to the Inland Empire east of Los Angeles, because that’s where many distribution centers are located, Cameron said. The hydrogen fuel-cell trucks would be helpful for moving that cargo to distribution points up to 100 miles away, he said.

Brouwer said the same applies to the campus buses at UC Irvine.

“On our campus, for example, we have mostly short routes,” Brouwer said, noting the university soon will meet all those short-route demands with battery-electric buses. “But then we have a few long routes, and for those routes we are already using fuel-cell buses,” he said, adding that the university installed one of the first hydrogen stations in the United States in 2002. “We’ve had an operating hydrogen fueling station on our campus for 15 years.”

Unlike pure battery-electric vehicles, the fuel-cell range-extended battery drivetrain is similar in refueling time to today’s fossil-fueled light-, medium- and heavy-duty commercial vehicles, said Morry Markowitz, president of the Fuel Cell & Hydrogen Energy Association.

“The key advantages of fuel-cell technology, especially in light trucks and passenger cars, is its ability to replicate the current driving experience,” Markowitz said.

Being able to drive a passenger car 300 to 400 miles on a full tank and refuel that vehicle in three to five minutes “gives the fuel-cell vehicle a much faster throughput at the pump compared to a battery-electric that may take an hour, even at a fast charging station.”

“The same can hold true for the larger medium- and heavy-duty commercial vehicle,” Markowitz said. “Fuel cells are scalable, so that you’re able to increase the energy output of a fuel cell in a heavy-duty vehicle to meet whatever weight requirements or horsepower requirement you need to pull the cargo you’re trying to move across the country,” he said.

UPS Inc.

Meanwhile, UPS Inc. is gaining experience with the fuel-cell range extension of battery trucks in its pioneering package car test fleet. The company is validating its first fuel-cell electric vehicle prototype in Sacramento, Calif., where its design and core performance requirements are being tested on the street, said Mark Wallace, UPS senior vice president of global engineering and sustainability.

Current project plans call for additional UPS trucks to be validated with at least 5,000 hours of in-service operations. All of the trucks will be deployed in California due to the state’s ongoing investment in zero-tailpipe emission transportation and the installation of hydrogen fueling stations around the state.

“The challenge we face with fuel-cell technology is to ensure the design can meet the unique operational demands of our delivery vehicles on a commercial scale,” Wallace said. “This project is an essential step to test the zero-tailpipe emissions technology and vehicles on the road for UPS and the transportation industry. We hope that by bringing our unique expertise to the development of hydrogen fuels, we can help advance the technology.”