Goodyear Tire Management System Is A Complete Solution

Fleets spend a significant amount of money on tires for their tractors and trailers between the initial purchase price of the tires themselves and the cost of retreading those tires. Tires also are a major contributor to the fuel efficiency of a truck. And tires can cause issues for fleet managers as it is estimated that tire problems account for 50% of roadside breakdowns.

The Benefits Of A Tire Management Program

Goodyear’s tire management program helps monitor tire performance and can help provide the following benefits:

- Streamlines a fleet’s tire operations

- Increases efficiency

- Reduces downtime

- Prevents problems such as breakdowns and emergency service

- Can be customized to meet the unique needs of each fleet

A proper tire management program along with early warning of developing issues allows fleets to get the most out of their tire investment while reducing some of the problems associated with improper tire inflation and tread wear.

Goodyear Tire Management is a comprehensive tire management program in which Goodyear helps fleets monitor their tires and provides actionable and insightful information to activate repair services where needed. It streamlines fleet tire operations, increases efficiency and reduces downtime. In addition, it allows the fleet manager to focus on other things like meeting delivery deadlines, optimizing routes, handling driver-related issues, etc.

Goodyear’s Tire Management is custom-designed to meet the specific needs of each fleet. There is no standardized solution when it comes to fleet operations just like there is no one one-size-all when it comes to tire management. Goodyear works with each fleet to provide the solution that best meets the fleet’s needs.

The Core Tenets Of Goodyear’s Tire Management Program

Goodyear’s Tire Management program is based on three key tenets.

- The first is tire monitoring. This includes digital inspections, automated inspections and real-time active monitoring.

- Next is the insights and analysis Goodyear provides to the fleet. All the data that is collected is transmitted to the Goodyear Mobility Cloud and actionable insights are provided based on the fleet’s unique specifications. Fleet managers can access reports and alerts through Goodyear’s Fleet Central online reporting tool to help them proactively manage critical tire data.

- Service activation is the third part of the program. Fleets have 24/7 access to industry leading roadside assistance from more than 2,300 Goodyear Commercial Tire & Service Network locations if they encounter problems with a tire. If the fleet desires, service is coordinated through Goodyear Fleet HQ , but following an alert of a tire problem, the fleet can choose to dispatch its own personnel to handle the problem. Either way, Goodyear alerts them when there is an emerging problem with a tire.

With options for monitoring, data analysis and service in place, it is essential to integrate them into the fleet’s existing operations and maintenance platforms.

Tools That Help

There are a variety of tools fleets can use to collect data and information about their vehicles’ tires. Some tools make more sense in certain types of fleet operations than others.

Tire Optix is a digital inspection toolset that allows fleets to capture data accurately and efficiently and provides instantaneous results. It simplifies data collection and provides a historic record of tire performance.

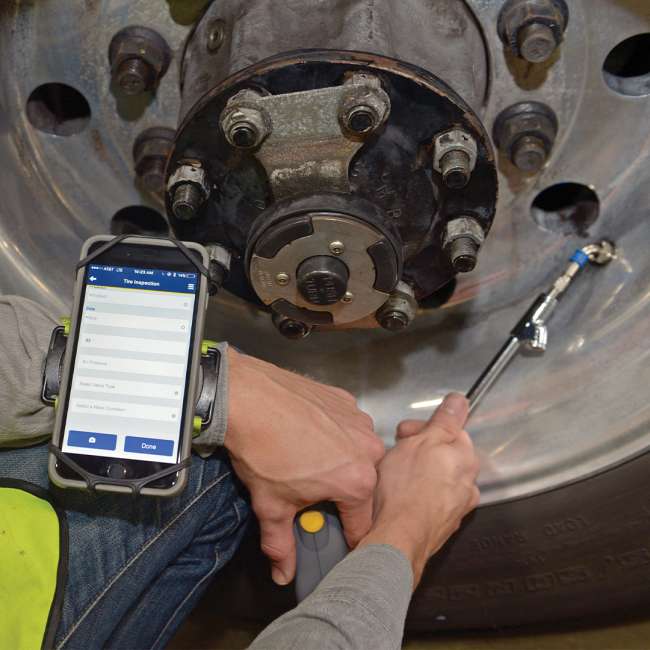

Tire Optix combines an app with a bluetooth handheld gauge that is used to record tire pressure, tread depth and tire condition. Goodyear recommends cellphones be used to capture the data, but the app also works on tablets whether Android or iOS. Tire Optix is suitable for use by fleets of all sizes.

The tool captures data and converts it into a customized report that is reviewed with the customer during the consultation phase. According to Mike Grima, senior director of maintenance at Roadrunner, “[Tire Optix] is the prevention rather than the cure and that prevention is worth its weight in gold.” Any size fleet can use this tool to gather information on tire pressure, tread depth and tire wear conditions. Fleets also can use Tire Optix for trailer readiness inspections to check lights and brakes as well as make sure the trailer is DOT compliant.

Magnum Express’ Todd Abke explains that prior to using Tire Optix, the fleet used pen and paper to write down the pressure and tread depth of each tire by position and trailer number. “It was not going anywhere. It was too much manual entry to try to get it into a database.” The fleet would look at what had been done but there was no ability to track history. Tire Optix gives Magnum tire information immediately to make service decisions before a unit leaves their lot. It also can store data over time to run performance metrics and forecast needs or issues.

Tire Optix has been used to check the condition of two million tires a year; 16% of which are found to need service. Of those needing service, 85% have air pressure issues, 7% have tread depth issues and 10% of the issues are related to mechanical wear.

Goodyear TPMS Plus is a connected, active tire monitoring system that goes beyond the benefits of traditional dashboard monitoring. Sensors on the tires are connected to the vehicle’s telematics device to measure tire pressure, temperature and the truck’s GPS location

Sensors can either be wheel mounted (inside mount) or mounted to the valve cap stem (outside mount).

Goodyear uses unique, fleet-specific algorithms to identify critical tire issues, inflation trends and more. This allows fleets of any size to be proactive in making tire-related decisions rather than simply reacting when a problem occurs. It can identify slow and fast leaks as well as high tire temperatures. Increased tire temperature is an indication of a developing problem with brakes, bearings or wheel seals.

Active monitoring of tire pressure via a device that is constantly collecting data allows fleets to see slow leaks in tires and fix them before they lead to an on-road breakdown. Reporting is typically done every 15 minutes, but fleets can adjust that to get data more frequently depending on their needs. Fleets have access to data over time which allows them to take a more predictive approach in bringing trucks or trailers in for service.

Jeremy Laskos, group manager, intermodal maintenance at Norfolk Southern Corp. says that understanding tire inflation alone is not the key to successful tire management. “Tire pressure monitoring is how we get real-time notification. It is how you manage the business going forward.” He also believes that Goodyear’s TPMS Plus should be able to help drivers as well. Given the driver shortage anything a fleet can do to help the driver — especially something that helps a driver keep the truck on the road — is going to be a great recruiting and retention tool.

Goodyear CheckPoint provides automated inspections of tire pressure and tread depth. The truck drives over a reader that captures data — tire pressure, tread depth and axle load — automatically. Data is immediately available for the fleet to review. It is best suited for large fleets with 200 or more vehicles or mixed service fleets of 100 or more units. CheckPoint enables large numbers of vehicles to be inspected and provides a snapshot of tire health that is updated frequently.

To learn more about how tire management can help your fleet, sign-up for a free fleet consultation on the Goodyear website.

The above article is sponsor-generated content. To learn more about sponsor-generated content, click here.