Electrical Skills Are Critical

As an ever-increasing array of devices, motive power systems and technologies asserts itself into the trucking industry, cutting-edge electrical knowledge and skills will be absolute necessities for technicians to keep fleet equipment operating at peak efficiency.

Discovering where the trucking industry stands in this area is the focus of a summer-long evaluation that American Trucking Associations’ Technology & Maintenance Council (TMC) is conducting. The results will indicate if the industry is prepared to maintain the next wave of technological innovations or instead face a knowledge crisis among its technician corps.

Legler

Many foresee that 24- and/or 48-volt electrical systems are just around the corner for U.S. fleets. When that happens, a mix of electrical system voltages will have to coexist for the indefinite future. The last time this occurred in our industry was during the great conversion from six- to 12-volt systems in the late 1950s to early 1960s, and it was more than a decade before all that was sorted out.

Data collection systems and technologies will have to share the same power sources and information transmission wiring to/from the J1939 databus with safety critical systems. Fundamental to maintaining and troubleshooting these systems is a solid understanding of all things electrical. Installations of new electrically powered equipment and technologies must be safely accomplished and must be done so in a manner that does not compromise the operation of other onboard systems.

But, are we ready as an industry to maintain these efficiency enhancing, forward-looking technologies? Will the multimeter become a more important tool (if it isn’t already) than the torque wrench? And, most importantly, will our technicians be able to troubleshoot errant electrons and sensors that feed faulty data into the telematics system as well as they can find and correct a chronic air leak that is allowing a brake to drag?

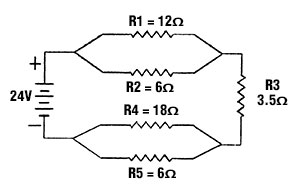

Do you know what happens if one of the resistors in the circuit diagram (See Figure 1) shorts out? How do you figure out which one? How does the change in current affect any powered device that may happen to be in this circuit? How does that then affect the operation of the truck? Should you even put the truck out on the route?

Figure 1

“I have been doing electrical training for technicians for the last 40 years,” said Bruce Purkey, chief creative engineer at Purkeys. “What I have found is a real weakness in using mulitmeters and other electrical testers such as battery testers. While most technicians can use them, their understanding of what the equipment results mean is lacking. All service bulletins are written with the assumption that the reader is skilled with all functions of the multimeter, which we find is not the case.”

To this end, TMC’s S.1 Electrical Study Group is conducting an assessment of fleet and service provider technicians in order to evaluate the current state of electrical knowledge. The cumulative results will be analyzed and presented at the S.1 Study Group Session during TMC’s 2018 Fall Meeting in Orlando, Fla., in September.

The assessment is based on TMC Recommended Practice 1204, Mechanic’s Electrical Skill Evaluation, which was developed by the council’s S.12 On-Board Vehicle Electronics Study Group.

While the assessment does not ensure that the technician has the required mechanical skills for troubleshooting truck electrical systems, it will provide a benchmark for knowledge training and reinforcement.

“We are looking for where we stand as an industry today with the use of multimeters and electrical troubleshooting,” said Chris DiSantis, director of training and field technical support for Aim NationaLease, who is the chairman of S.1. “The industry presently struggles with 12-volt systems, and the jump to 48 volts or higher is coming rapidly.”

“We need to set the stage for how to train our current and future workforce for the challenges these new systems will hold,” he said.

What kind of meters are depicted in the diagram in Figure 2? Which one would you use to diagnose a malfunctioning sensor to determine if the sensor was faulty or if there was a problem elsewhere in the circuit?

The new and updated questions being used in this assessment also will assist TMC in revising RP 1204 to reflect the current state of truck electrical systems and will evaluate the technician’s knowledge in the following areas:

• Understanding of basic electrical concepts.

• Reading simple electrical wiring diagrams with electrical symbols.

• Performing circuit measurements with a volt-ohm meter.

• Solving basic circuit equations using Ohm’s Law.

• Knowledge regarding the databus.

The questions are divided into four categories: “Fundamental,” “Application,” “Advanced” and “Databus.”

Figure 2

In the “Fundamental” section, questions address basic electrical topics such as conductors and insulators. In the “Application” section, questions stress familiarity with and ability to use a (volt-ohm) multimeter. The “Advanced” section questions generally can be considered beyond the required basic knowledge for a technician to do electronic system maintenance on trucks.

Ideally, technicians who have responsibilities for truck electrical system maintenance should achieve a minimum of 85% correct responses to the “Fundamental,” “Application,” and the “Databus” category questions. Technicians who score 85% on the “Advanced” questions have demonstrated an excellent understanding of basic electrical theory.

“This survey was developed so that we can pinpoint actual areas where real weakness is so that training can be developed to address weakness,” said Purkey, who also serves as vice chairman of S.1. “With a large population taking this test, we should be able to make some good assumptions and make good recommendations how fleets can address these issue and improve their technicians’ skill levels in this area.”

How important is coming to grips with this knowledge gap? TMC’s preliminary test of the survey in late May revealed that the vast majority (nearly 3/4) of those taking the assessment did not attain the competency benchmark. Whether this early trend represents a trickle or a tidal wave of a challenge to the industry will be revealed at the S.1 technical session on Sept. 19 during the fall meeting.

TMC is currently conducting the assessment online, and the test is open to all technicians through Aug. 15. The answers in this quiz are randomized for each participant, so it is not possible to exchange information regarding correct answers using a “key” sheet. Following completion, TMC will post the correct answers as a proposed update to RP 1204 via its online community, TMC Connect.

To access the assessment, go to: www.research.net/r/ELECTRICTECH18.

TMC encourages fleet managers to share this link with their technicians to help determine their electrical/electronic technicians’ current abilities and then consider what their operation needs to do to prepare for the next generation of electrics/electronics.

As Technical Director of ATA’s Technology & Maintenance Council, Jack Legler manages the council’s recommended practice development process.