Automatic Inflation Tech Expands to Tractor Tires

Systems that monitor tire pressure and automatically add air when needed have been available in trucking for more than 20 years. But the use of these automatic tire inflation systems, or ATIS, has been limited because they have only been able to service the tires on trailers. Now, that’s finally changing.

More ATIS products are hitting the market that promise they can monitor air pressure and automatically inflate tires not only on the trailer, but also on the tractor drive and steer axles.

While the benefits from these systems are quite clear, widespread adoption has not been rapid. There’s been a delay in government regulations requiring these devices or their cousins, tire pressure monitoring systems, or TPMS, on new trailers. And there are major challenges in engineering ATIS for tractors.

Currently, the ATIS market mainly consists of products sold by about half a dozen companies, but only about half are offering it for tractors. All but one of them use a method of moving air from the truck’s air system through hoses or axles to get air into the tires.

Pressure Systems International is generally regarded as the originator of ATIS nearly 25 years ago. Its system, which can be purchased directly from the company but also is marketed as the Meritor Tire Inflation System by P.S.I., is available at the OEM and aftermarket levels. The company has concentrated on offering automatic inflation for trailers, but that’s starting to change.

“We have been working on a system for trucks and drive axles that we recently put into limited production,” said Jim Sharkey, P.S.I. vice president of sales and marketing. “Our system is adaptable for the steer axle, [but] we’re still a little cautious about putting it there because of some of the reliability involved.”

According to Sharkey, the problem isn’t just getting air to tires on the steer axle; it’s also the exposure of the hoses to possible damage. In the meantime, P.S.I. is looking for what Sharkey called a “bulletproof” solution, but so far that doesn’t seem to be a problem.

“We are getting a lot of fleets that are telling us they’re OK with the front not having ATIS,” he said, noting that one very large national fleet that did not wish to be identified has been running P.S.I.’s truck ATIS system and is not concerned that it’s not available on the steer axle.

Of the other two major players, one is a familiar name and the other is a fairly recent entrant.

Dana recently started offering the Spicer OpTiMa tire pressure management system. It was introduced in 2017 with full production set for the middle of this year. Available at the OEM level, the system is designed for every tire on a tractor-trailer.

According to Steve Slesinski, director of global product planning for Dana’s commercial vehicle group, Spicer OpTiMa is based on the central tire inflation system Dana developed for military vehicles long ago, which allows active tire inflation and deflation based upon the terrain.

“Dana actually leveraged that technology to create a system that was more appropriate for commercial vehicles,” he said. “The benefits of ATIS you’ve seen on trailers over the last several years can now be applied to [tractors and trucks] with the Dana system, because we found a way to move the air from the chassis into the wheel ends, drive axles and steer axle.”

Unlike other ATIS systems, Aperia's bolt-on Halo uses the wheel's rotational model to keep tires inflated. (Aperia Technologies)

Aperia Technologies took a different approach with its Halo Tire Inflator. Rather than relying on hoses to move air to the tires from a rig’s air pressure system, it uses an entirely different method to keep tires inflated.

As Aperia CEO Josh Carter described it, “Halo is like a self-winding watch that’s installed at the wheel end that generates its own pumping power as a truck moves down the road.”

Introduced in 2014, Halo is an aftermarket product that the company said can be installed in a matter of minutes. One of its biggest customers has been Ryder System Inc., which announced in September that it signed an agreement with Aperia making Halo the standard specification for the company’s heavy-duty commercial rental fleet.

The reasons were customer-based, said Nic Signorini, Ryder director of supply management.

“It was a combination of fuel-efficiency advantage that we could provide to our customers,” he said, “as well as peace of mind when it comes to on-time deliveries and minimizing downtime issues due to tire breakdown events due to underinflated tires.”

The kind of benefits Signorini described aren’t unique to any specific automatic tire inflation system. Estimates show a significant percentage of truck tires are underinflated by at least 20%, technically running flat, according to numerous sources. And because underinflated tires are one of the top causes of tire failures that lead to roadside service calls, it seems clear why ATIS has increased in popularity on trailers.

Full-service truck leasing company Idealease has been testing the Dana Spicer OpTiMa system, and the results have been positive, said Andy McEnaney, vice president of affiliate services. Initial results show the system helps maximize vehicle uptime, increases fuel economy and reduces over-the-road costs.

“Due to positive results we’ve seen from our initial testing, we’re actively increasing our test sample in the first quarter of 2018,” he said.

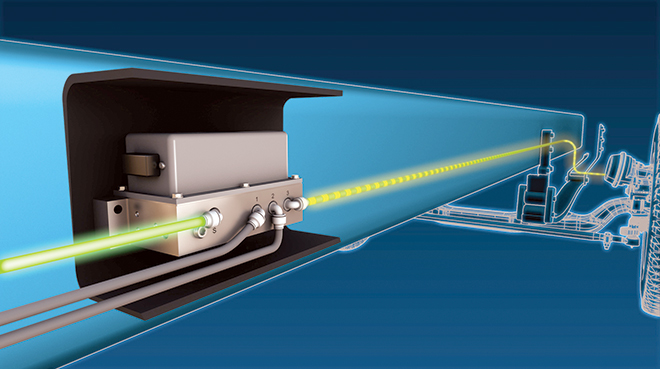

Automatic tire inflation technology such as Dana's Spicer OpTiMa system is designed to prevent tire failures and improve fuel economy. (Dana Inc.)

With such promising results, why aren’t all the providers of ATIS for trailers already on the bandwagon when it comes to offering it for tractors?

Much of the reason has do with the drive axle, according to Matt Wilson, business unit director for Hendrickson, which offers Tiremaax, an ATIS for trailers only.

“On the steer axle, the configuration is very similar to a trailer and is relatively easy to do with technology that’s currently used on trailers,” he explained. “The issue with the drive axle is that the axle components themselves consume the location that typically an air line or air cavity for tire inflation would occupy.”

That’s one likely reason why companies such as P.S.I. offer a solution for the drive axles by using what Sharkey called an “external system,” in which a supply line tapped into the air tank runs out from underneath the fifth wheel and splits into two lines going to the front and rear tandem axles.

As Sharkey explained it, P.S.I. basically takes the rotary union used to deliver air to the tires on trailers and reverses it so it supplies air to the drive axle tires from just outside of the axle shaft itself.

Another company that cites the challenges in designing systems for tractors is Stemco, which introduced its Aeris tire inflation system for trailers in 2012.

Prashanth Kamath, segment business leader at Stemco, said the company has no plans to go beyond its current offering, and he expressed doubts about current ATIS available for tractors.

“The technology isn’t quite there yet to handle the same level of scenarios or inflation that’s available on trailers,” he said.

However, others, such as Ryder’s Signorini, say having ATIS installed on tractors is an obvious decision with a good return on investment. And there are safety benefits he described as tremendous.

When asked what advice he would give a fleet considering ATIS, Signorini said, “I would encourage them to run their own return-on-investment scenarios based on the mileage and applications they’re running, including the estimated benefits that you are going to see from a fuel and tire perspective,” he said. “Do you have specific targets in mind that you are trying to reach? Certainly, ATIS could be one of those levers to pull.”